Hard Failures

Hard failures cause the Check Engine light to illuminate and remain

on until the problem is repaired. If the light comes on and remains

on (light may flash) during vehicle operation, the cause of the

malfunction can be determined using the diagnostic code charts.

If a sensor fails, the computer will use a substitute value in its

calculations to attempt to continue engine operation. In this

condition, commonly known as “limp-in” mode, the vehicle

may run but drivability will be poor.

Intermittent Failures

Intermittent failures may cause the Check Engine light to flicker or

illuminate and go our after the intermittent fault goes away.

However, the corresponding code will be retained in the computer

memory. If a related fault does not reoccur within a certain time

frame, the code will be erased from the computer memory. Intermittent

failures may be caused by sensor, connector or wiring related

problems.

Retrieving Codes

Using the jumper wire, connect the green single connector (on the

firewall below the windshield wiper motor) to ground.

With the ignition On and engine Off, observe the check engine light.

Note any codes and record them on a piece of paper. Check the trouble

code table for possible cause(s).

If the light remains on continuously, the check engine light circuit

is grounded or the computer is defective. If the light does not

illuminate there are no trouble codes stored.

Clearing Codes

After necessary repairs have been made, disconnect the negative

battery cable. Depress the brake pedal for at least 5 seconds.

Reconnect the battery cable.

CODE 01

Computer is sensing poor or no Ignition Pulse. Check for any poor

connections at the ignition coil. The coil may be failing; measure

the resistance of the primary and secondary coils.

Primary coil resistance is measured between the two small terminals

on the coil. Resistance should be between 0.72 and 0.88 W.

Secondary coil resistance is measured between the negative terminal

(yellow/blue wire) and the high tension terminal (plug wire).

Resistance should be between 6 and 30 kW.

If the coil checks out OK, or replacing it with a known good coil

does not work, check for continuity between coil negative wire

(yellow/blue) and the computer terminal 1M. Terminal 1M is on the

top, sixth from the left (yellow/blue wire).

CODE 03

Computer is not receiving a good G Signal from the distributor. Check

the distributor connections and repair if necessary. If the

connectors check out OK, measure the voltage at terminal 1N of the

computer with the engine at idle. Terminal 1N is on the bottom, sixth

from the left (yellow wire).

If there is no voltage there may be a break in the wire between

terminal 1N and the distributor, or the G Signal generator inside the

distributor may be defective. If the voltage measures approximately

3.0 volts then the problem may be in the computer itself.

CODE 08

Computer is reading incorrect or no signal from the Air Flow Meter.

Check the large electrical connector on the Air Flow Meter for poor

connections, also check for any possible intake tract leaks. If no

problems are found, next check the resistance of the Air Flow Meter

(see chart).

CODE

09

The computer is receiving an incorrect signal from the Water Thermo

Sensor. The Water Thermo Sensor is located on the back side of the

engine below the intake manifold. It is fairly difficult to get to

(above the starter). The best way to reach it is from underneath the

car . Removing the oil filter helps . Check the connector first for

any possible bad connection. If the connection looks OK then check

the resistance of the sensor. You may need to remove the sensor to

test it (some coolant will drain out). The resistance between the two

terminals at 68 degrees should be 2.21- 2.69 kW . If the sensor is

warmed up to 176 degrees the resistance should drop to 0.290 -

0.354 kW. If the sensor fails these tests it should be replaced.

CODE 10

The computer is receiving an incorrect signal from the Intake Air

Thermo Sensor. The sensor is located inside the Air Flow Meter . Open

up the air box and look underneath the top section at the bottom of

the Air Flow Meter. This is where the Intake Air Thermo Sensor is

located. First check the connections at the Air Flow Meter. If this

checks out OK, then check the resistance of the sensor. To do this

measure the resistance between terminals E2 and THA (see chart). Heat

the sensor with a light bulb to obtain the different temperature

readings. If the sensor tests bad the Air Flow Meter must be

replaced. If the sensor tests OK then the problem is most likely in

the wiring harness.

CODE 12

The computer is receiving poor information from the Throttle Position

Sensor. The first step is to check the connections at the sensor and

repair if necessary. Next check the resistance and voltage at the

Throttle Position Sensor by removing the rubber boot from the

connector and turning on the ignition. Check the voltage between each

terminal and ground (see chart). If terminal D only is incorrect the

sensor may be out of adjustment. If others are incorrect check the

resistance between the terminals (see chart).If the resistance is

incorrect the Throttle Position Sensor needs to be replaced. If

everything seems OK the problem may be in the wiring harness.

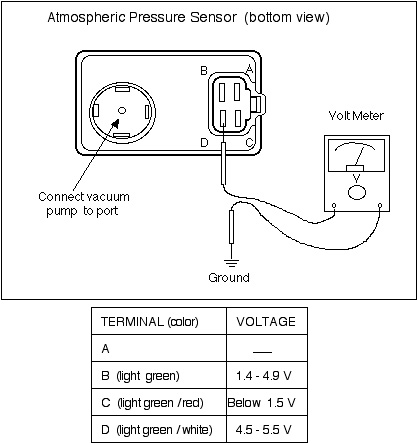

CODE 14

The computer is not receiving correct signals from the Atmospheric

Pressure Sensor. The Sensor is located on the upper firewall on the

passenger side. Locate the Sensor, remove the rubber cap, and connect

a vacuum pump to the port. Use the diagram and chart to check

the voltage between each terminal and ground while applying and

releasing vacuum to the Sensor.

If the voltage at C or D terminal is not correct, check the wiring

harness. If the voltage at terminals C and D are OK but terminal B is

wrong, the Sensor should be replaced.

CODE 15

The computer has not sensed voltage above 0.55v from the Oxygen

Sensor 120 seconds after the engine speed passed beyond 1,500 rpm.

Check the green single connector for the Oxygen Sensor at the

driver’s side end of the cylinder head. If the connector and the

wires look OK, then the problem is most likely in the Oxygen

Sensor.

To test the Oxygen Sensor, warm up the engine and let it run at idle.

Disconnect the Oxygen Sensor at the green connector and using a

digital volt meter, measure the voltage between the sensor and

ground. At idle the voltage should vary between 0.3 and 0.7 volts.

Next run the engine at 4,000rpm until the volt meter reads about 0.7

volts. Rev the engine several times while reading the volt meter. On

acceleration the voltage should be between 0.5 and 1.0 volts (rich).

On de-acceleration the voltage should drop to between 0 to 0.3 volts

(lean). If the Oxygen Sensor does not perform as listed above,

replace the sensor.

CODE 17

The Oxygen Sensor output voltage is below 0.45 volts 20 seconds after

the engine has passed 1,500rpm. This code may indicate a faulty

Oxygen Sensor (see test procedure in code 15). This code can also

indicate an over-lean condition. Check also for any possible intake

air leaks, or leaks in any vacuum hoses or emission components. Check

the spark plugs also; clean or replace if necessary.

CODE 25, 26, 27

These codes are for the three solenoid valves on the center of the

firewall. Generally an indicated fault will be caused by faulty

wiring or a poor electrical connection. If the wiring and

connections check OK then test the solenoid valve itself. Without

voltage applied to the solenoid air should not flow through the valve

from one hose port to the other. With 12volts applied to the two

terminals of the solenoid air should flow through from one hose port

to the other. If the solenoid valve fails this test, replace it.

Code 25 is the solenoid valve for the fuel pressure regulator. Of the

three valves it is the one on the driver’s side. This

valve cuts off

vacuum to the fuel pressure regulator when the engine is warm for 2

minutes after the engine is started. This temporarily raises

the fuel pressure to help prevent vapor lock.

Code 26 is the solenoid valve in the center that operates the vacuum

switch valve. Code 27 is the solenoid valve on the passenger side and

operates the no. 1 purge control valve. These two solenoids combine

to allow fumes from the fuel tank to enter the intake manifold and be

burned.

CODE 34

The computer is detecting a problem with the BAC valve. The BAC

(Bypass Air Control) valve is part of the Idle Speed Control System.

The ISC system allows metered air to bypass around the throttle plate

to maintain a steady idle. The BAC valve operates only when the

engine is cold, similar to what a choke would do on a carbureted car.

The ISC valve operates all the time to maintain a constant idle

speed. The BAC valve is located on the back side of the

intake manifold all the way to the passenger side.

The BAC valve has two large hoses running to it, one from the intake

pipe on top of the valve cover to the BAC valve and the other runs

from the BAC valve to the intake manifold. First check the electrical

connection to the BAC valve, this is the most likely spot for

trouble. If the wiring checks OK then check the operation of the BAC

valve.

The following tests are performed with the engine off. To check

the BAC valve, disconnect the air hose from the funnel-shaped air

intake pipe. Blow through the valve and check the air flow. With the

engine cold air should flow; with the engine warm, air should not

flow. To check the Idle Speed Control valve , unplug the electrical

connector to the BAC valve. Connect an ohmmeter to the terminals of

the BAC valve and check the resistance. Resistance should be between

5-20 W .