Reprinted with permission from Sport Compact Car, June 1999

Reprinted with permission from Sport Compact Car, June 1999

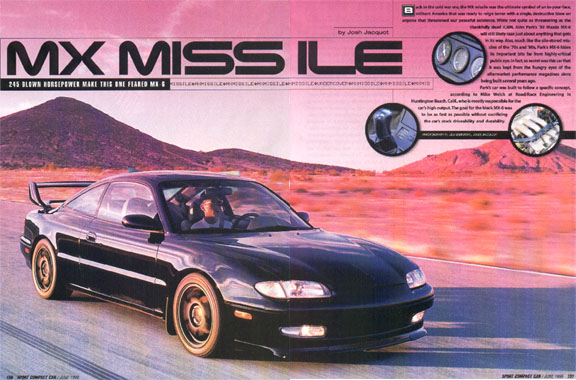

Back in the cold war era, the MX missile was the ultimate symbol of an in-your-face militant America that was ready to reign terror with a single, destructive blow on anyone that threatened our peaceful existence. While not quite as threatening as the thankfully dead ICBM, John Park’s ’93 Mazda MX-6 will still likely raze just about anything that gets in its way. Also, much like the silo-stored missiles of the ‘70s and ‘80s, Park’s MX-6 hides its important bits far from highly-critical public eye. In fact, so secret was this car that it was kept from the hungry eyes of the aftermarket performance magazines since being built several years ago.

Park’s car was built to follow a specific concept, according to Mike Welch at Road/Race Engineering in Huntington Beach, Calif., who is mostly responsible for the car’s high output. The goal for the black MX-6 was to be as fast as possible without sacrificing the car’s stock driveability and durability. That means that Park’s MX-6 is still packing functional air conditioning, power steering and other accessories just as it came from the factory.

Park

came to Welch wanting an advantage over most anything he might

encounter at the stop light grand prix. But, he wanted to be able to

do the trouncing with three of his buddies in the car and the air

conditioning blasting. He also required that the car do all this

without raising the eyebrows of anyone who looked under the

hood; a tall order for a front-drive car that weighs more than

3,000 lbs.

Park

came to Welch wanting an advantage over most anything he might

encounter at the stop light grand prix. But, he wanted to be able to

do the trouncing with three of his buddies in the car and the air

conditioning blasting. He also required that the car do all this

without raising the eyebrows of anyone who looked under the

hood; a tall order for a front-drive car that weighs more than

3,000 lbs.

Countless hours of work in the form of custom design and fabrication went into transforming the MX-6 into the phenomenal machine that it is today Before installing the supercharger, Welch recommended that Park drive the car for about three months to break in the engine.

John Mueller at Road/Race began work on the car by removing and disassembling the engine. Knowing that the V6’s stock compression ratio wouldn’t mix well with forced induction, Mueller modified the car’s cylinder heads by removing excess material from the combustion chambers, effectively lowering the compression ratio by .5 lbs. He also performed a competition valve job while the valves were back cut and swirl polished. The four-valve heads were ported as was the intake manifold. The engine’s stock cam profiles were retained.

Mueller bored the engine .020 inches and used OE pistons with ceramic-coated domes. Connecting rods are polished and shot peened while the crank was balanced and polished. An Earl’s oil cooler was plumbed into the car’s wet sump lubrication system to help reduce thermal stress on the engine brought about by forced induction. Welch also installed a turbo timer to allow for proper cooling of all components in the engine.

After the break-in period, with the engine readied for the addition of a supercharger, Welch began fabricating the necessary mounting hardware underneath the car. The Powerdyne centrifugal supercharger is sized for a 5.0-liter Mustang. It sits low and completely out of sight in the left front corner of the engine compartment where it is shaft driven by a series of toothed belts and a 1-inch driveshaft that transmit power from the front of the transverse-mounted V6 to near the back of the engine where the blower is mounted. A belt from the crank pulley turns the shaft, which, in turn, spins the supercharger via another belt and pulley.

The

supercharger uses ceramic bearings and an internal belt drive. The

belt and bearings last about 30,00 miles before needing a $450

rebuild, according to Welch. Otherwise, the system is relatively

maintenance free, requiring only occasional lubrication and cleaning

of the industrial bearings used to support the driveshaft. The shaft

turns at 11,900 rpm at a maximum engine speed of 7000 rpm. An

aluminum skidplate was fabricated to protect the supercharger’s

low-mounted drive system.

The

supercharger uses ceramic bearings and an internal belt drive. The

belt and bearings last about 30,00 miles before needing a $450

rebuild, according to Welch. Otherwise, the system is relatively

maintenance free, requiring only occasional lubrication and cleaning

of the industrial bearings used to support the driveshaft. The shaft

turns at 11,900 rpm at a maximum engine speed of 7000 rpm. An

aluminum skidplate was fabricated to protect the supercharger’s

low-mounted drive system.

The entire setup is practically invisible from the top of the engine bay as though the intake is routed below the car to collect cold air. A UNI foam filter feeds the supercharger via a 3-inch hose, while a Bosch compressor bypass valve bleeds excess pressure.

Additional fuel delivery is now accomplished via two HKS 550cc injectors installed just aft of the air flow meter before charged air enters the manifold. A rising rate fuel pressure regulator is used in conjunction with an HKS Additional Injector Controller allowing up to 12 psi boost. A Denso in-tank fuel pump maintains fuel pressure.

Hot Shot headers were used in place of the stock exhaust manifolds, while a Stromung 2.5-inch exhaust system takes the place of the less efficient stock system. The exhaust system also uses a 2.5-inch high-flow catalytic converter.

A J&S

Electronics knock retard sensor was installed allowing Welch to

advance the engine’s timing without fear of damage from

detonation. The J&S unit retards timing on only the cylinders

knocking. Installed in the cabin are a J&S air/fuel ratio meter

and knock retard meter, allowing Park to keep an eye on the

engine’s on-boost performance. Also installed are HKS boost,

exhaust gas temperature and oil temperature gauges.

A J&S

Electronics knock retard sensor was installed allowing Welch to

advance the engine’s timing without fear of damage from

detonation. The J&S unit retards timing on only the cylinders

knocking. Installed in the cabin are a J&S air/fuel ratio meter

and knock retard meter, allowing Park to keep an eye on the

engine’s on-boost performance. Also installed are HKS boost,

exhaust gas temperature and oil temperature gauges.

Stock suspension bits were replaced with adjustable Carrera threaded body coil over shocks, which allow the car’s ride height to be adjusted as needed. Road/Race also designed and built front and rear strut tower braces. The front shocks are a full 1 inch shorter than stock, requiring the use of custom camber plates from Road/Race. Welch also installed Power Slot rotors and Repco Metal Master brake pads. Steel braided brake lines are used with Motul brake fluid to enhance brake performance.

The final touches on Park’s MX-6 were cosmetic. Road/Race

combined an aftermarket wing designed for an RX-7 and the stock wing

from the MX-6 at the rear of the body eliminating the near-stock

appearance of the MX-6. A Japanese Mazdaspeed front spoiler was adapted to fit the bumper of the

American MX-6 to give the car a more aggressive stance, while all

factory emblems and the trunk lock cylinder were shaved. Park chose

16x8-inch wheels from the third-generation RX-7 because of their

light 13.5-lb weight. Although not as massive as the rolling stock

found on many of today’s hot imports, the lightweight wheels

serve their purpose well. Park had the wheels painted black to match

the rest of the car.

Mazdaspeed front spoiler was adapted to fit the bumper of the

American MX-6 to give the car a more aggressive stance, while all

factory emblems and the trunk lock cylinder were shaved. Park chose

16x8-inch wheels from the third-generation RX-7 because of their

light 13.5-lb weight. Although not as massive as the rolling stock

found on many of today’s hot imports, the lightweight wheels

serve their purpose well. Park had the wheels painted black to match

the rest of the car.

While the MX-6 has only been put through the quarter-mile once, its times aren’t likely representative of its substantial power increase. The MX-6 ran a 14.0-second quarter-mile on street tires with massive amounts of wheelspin, according to Park. Both the car’s owner and its builders believe it’s capable of much better time given the right tires. Park is considering selling the car now that his secret is out of the bag, we can’t wait to see his next stealthy screamer.

Dyno ChartClick on chart for a larger image |

Click on any photo for a larger image.