SCC Magazine – Project Eclipse – Part Five

by Dave Coleman

PHOTOGRAPHY: LES BIDRAWN, KEITH BUGLEWICZ, DAVE COLEMAN

A 28-Horsepower clutch? well sort of ….

Project Eclipse has been the recipient of a very successful series of modifications. From the beginning, nearly everything we did to the car yielded very positive results. That all stopped with out last installment (September, 1998).

As you may recall, our last series of modifications began with a Hahn Racecraft (HRC 3-inch downpipe and high flow catalytic converter. That piece increased airflow so much that the fuel system maxed out the stock injectors just trying to keep up. This lead us to install larger, 550-cc/min injectors from RC Engineering and a larger fuel pump from Road/Race Engineering. The larger injectors required that we adjust the Apex Super AFC (the AFC adjusts the stock air mass sensor’s output so the computer can be fooled into delivering the shorter injector pulses needed for the larger injectors), Being short on time, we made our adjustments quickly and largely by the seat of our pants (and with the help of an Apex exhaust temperature gauge). The result was a car that sounded cool, sucked down a lot more gas, and made exactly the same power as it had before this series of changes. We were confident,, however, that the only reason the changes had not made power was the sloppiness of our tuning.

Shortly after we discovered the lack of improvement, we took the car back to Mike Welch at Road/Race for a more careful tuning session. Welch has tuned numerous Eclipses with the Super AFC and has the procedure pretty well nailed down. First, he plugs a laptop computer equipped with OBD Tool software into the diagnostic plug under the dash The OBD Tool software not only allows you to read the fault codes from the OBDII system, and to reset those fault codes (thereby turning off that annoying “check engine” light), but it also allows you to monitor and data log many of the stock ECU inputs or outputs.

There are five knobs on the Super AFC, each offsetting the air mass sensor’s output at a particular engine speed (the AFC creates a smooth line between these points to establish an overall offset curve). The first knob, which sets the 800-rpm point, is adjusted by simply letting the car idle while monitoring the 02 sensor voltage with the OBD Tool software. With the knob adjusted properly, the 02 sensor’s reading should constantly cycle up and down as the computer operates in its self adjusting closed loop mode. Given the fact that the RC Engineering injectors are 23 percent bigger than the stock injectors it is surprising that the first knob is turned down only a few percent to idle properly

For the next two knobs, covering the 2400 and 4000-rpm points, Welch adjusts them by logging 02 sensor voltage at full throttle in fourth gear. Using a lower gear would not load the engine enough, nor would it allow the engine to be in that rpm range long enough to easily see what is going on. Ideally, 02 sensor voltage should be about 0.94 volts as seen on the OBD II Tool. Under these conditions; ours was 0.98 volts when we brought it in-way too rich, according to Welch.

Finally, the last two knobs (5600 rpm and 7200 rpm) are adjusted by watching exhaust temperature at full throttle in fourth gear. It doesn’t take a rocket scientist to realize that watching the exhaust temperature gauge at the top of fourth gear requires either a closed race track or a trip to Montana with a notebook full of explanations for why 130 mph is reasonable and prudent. According to Welch, the exhaust temperature should be about 600 degrees C (about 1650 degrees F) at high rpm under maximum load. Before Welch made the adjustments, exhaust temperature never went over 800 degrees C, another sign that the engine was running too rich.

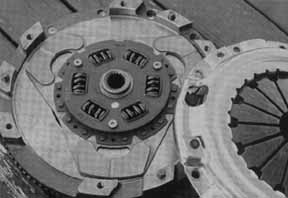

Our new Exedy clutch combines a three-puck cerametallic friction surface with a sprung clutch disc to provide incredible gripping power and heat resistance with reasonable driveability.

[RRE Note: we were not happy with the performance of the Exedy clutch and do not recommend it]

Even after tuning the AFC, Welch felt the car still wasn’t running right. No matter how he set the boost controller, boost pressure would always drop to about 15 psi by redline. With a stock turbo, this is to be expected, as it can not move enough air to make more boost at high-rpm. Welch’s experience with the Turbonetics-upgraded T28 turbo we were using, on the other hand, told him there should be more boost available. After investigating a few dead ends, the OBD Tool again offered the answer. By data logging speed and rpm during a hard fourth-gear pull, Welch noticed that instead of speed and rpm increasing in lock step as they should, the rpm line would start climbing away from the speed line. The only explanation was a slipping clutch.

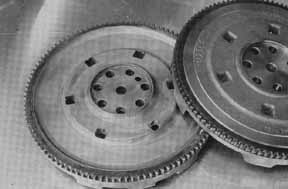

The Road/Race flywheel has four pounds of iron machined away, The majority of that weight was removed from the outer portion of the flywheel where the change can make the most difference. The stock flywheel on the right shows how much metal was removed.

A slipping clutch explains a lot about our experiences with the Eclipse. First, the loss of boost came from the loss of load. Spinning the clutch is easier than accelerating the car, and the lighter loading on the engine reduces the amount of boost it builds. A slipping clutch could also explain some of our inconsistent power measurements. From one installment to the next we have noticed some strange variations; in the power output of our all-wheel drive Eclipse as measured by our Vericom. Some of the variation could have been caused by differences in temperature affecting intercooler performance, or by the ECU switching to extra-conservative fuel and timing maps as weather conditions changed. Now we can add a slipping clutch to the list of things that could be changing power output at the wheels from run to run.

Given our Eclipse’s tremendous power, immense weight (over 3500 pounds with a driver) and all-wheel drive grip, a slipping clutch is no surprise. In fact, you might call it a design feature. In most cars, the clutch is designed to slip before driveline parts start to break- This is especially true of all-wheel drive Eclipses. With 210 horsepower and all wheel drive, there is a natural tendency for every common-sense-challenged yahoo who gets behind the wheel to try and spin all four tires. To save countless thousands of dollars in warrantee claims resulting when these same yahoos find out the transmission isn’t up to the task, the clutch in the GSX was designed with two safety features: An overall capacity a little on the low side, and a damper in the clutch’s hydraulic system that slows the clutch’s engagement when that yahoo makes his or her attempt. While the damper was not getting in our way (the clutch slipping problem only occurred at high boost, well after the clutch was fully engaged) the low capacity of the stock clutch was a problem.

With 210 horsepower and all wheel drive there is a natural tendency for every Common sense challenged Yahoo who gets behind the wheel to Try and spin all four tires

Now that we have learned that our stock clutch has been slipping for an indefinite period of time, we can’t be sure how accurate any of our previous runs were. Power output may have been lowered by the clutch on any of our previous runs. According to the now questionable readings of our Vericom, the new clutch, along with the downpipe and injectors, gave us a huge gain of 28 horsepower. Based on comparisons with rated flywheel horsepower versus Vericom horsepower on our Sentra SE-R (Technobabble, May ’98), we estimate the Eclipse’s flywheel output to be at least 294 horsepower.

Before installing a higher-capacity clutch, we made some 0 to 60 runs to get some objective idea of how much of a difference the new clutch was making. Launching a turbocharged all-wheel drive car is a challenge. While the tremendous grip can give you a serious advantage off the line, getting the car to leap off the line without either bogging before boost is built, or belching the transmission out the bottom of the car is a challenge. The fastest launches came by bringing the engine up to about 3000 rpm, and rapidly feeding out the clutch and feeding in the gas at the same time. Using this technique we were able to pull off one impressive 5.63-second run, followed by the distinctive stench of clutch flambé. The heat generated by that one launch was all the clutch could handle. After that one clutch-smoking run, we were never able to pull off another sub-six second pass.

Our new clutch would have to be significantly stronger, but since the Eclipse is still a street car driven almost every day, we needed it to provide good driveability without excessive pedal effort or chattering during engagement. Our decision to try a three-puck cerametallic

Exedy clutch may seem like a surprising choice oven our requirements. In most cases such a clutch would grab so suddenly and chatter so badly that it would be absolutely undriveable. Street clutches are typically designed with a sprang disc, meaning that the center of the clutch disc-where power is delivered to the transmission-is isolated from the outer edge of the disc-where the disc is clamped by the pressure plate by several springs. These springs smooth the clutch’s engagement. Most cerametallic clutches are designed with a solid disc simply because most sprung discs can’t handle the higher torque load. While it seems like the obvious solution is simply to build a stronger sprung disc, most performance clutch manufacturers make their clutches by modifying stock parts. Building a whole new disc would make the parts prohibitively expensive. Building performance clutches by modifying stock parts certainly works, but it does place some limitations on the design. Exedy, on the other hand, is a OE clutch manufacturer (Exedy actually owns Daiken Clutches), and they therefore have the facilities to be able to engineer and build clutches that most low volume manufacturers would not be able to. Hence their claim that their three-puck cerametallic clutch could be used on a street car.

The OBD Tool software Is used to monitor engine functions as tuning adjustments are made. The jagged line here is O2 sensor voltage cycling up and down as the computer self-adjusts fuel mixture at idle. The 800-rpm knob on the AFC must be set within the proper range to allow the computer to do this.

Here the OBD Tool is showing the data logged run that first revealed slipping clutch. The line on top is RPM, while the line on the bottom is speed. Both should increase together, but because of our slipping clutch, the rpm increased more than the speed.

That sounded like the perfect solution, so we decided to put their claim to the test. The Exedy clutch has a clamping force of 880 pounds compared to the stock clutch’s 700 pounds, but because the three-puck design concentrates that force into much smaller area (only three pucks instead of a full disc) the pressure on the friction surface is event higher. The result is an overall torque capacity 63 percent higher than the stock clutch.

When Road/Race installed the clutch, they suggested installing a lightened flywheel as well. While the Road/Race flywheel is only 4 lbs lighter than the stock one (14 lbs vs. 18 lbs), most of that weight has been removed from the outer edge of the flywheel where it can make the most difference. Since rotational inertia goes up with the square of the distance (in other words, removing weight from the outer edge will make four times as much good as removing it from halfway out from the center) where you remove weight makes much more difference than how much you remove.

After installing the clutch and flywheel, Welch drove the car for a day to help us break it in. Initially, he reported, the clutch did chatter and grab rather severely, but as the clutch broke in, engagement smoothed considerably Only a few days of normal driving were required before the clutch began to behave in a civilized manner Pedal effort is quite high, even though spring force is only 25 percent higher than stock. The fact that the stock clutch’s effort is already quite high makes 25 percent a significant difference. The clutch is also slightly grabby as any clutch this strong has to be, but overall, if you can cope with the clutch on an early ’80s Porsche 911, you cope with this one.

Next came the tests. With the clutch broken in, we returned to our 0-to-60 mph test. Launching the car is not really any easier with the stronger clutch-engage it too suddenly and you can still bog it quite easily, but now excessive slippage will not overheat the friction material. Much like brake pads, an organic clutch facing material will tend to “float” when overheating causes resins in the facing to bum off. The cerametallic facing has no such problem-heat has very, little effect on our new clutch’s performance. Excessive slippage is still a bad idea, though, as the clutch will tend to grab and chatter if you launch at too high an rpm. Once we found the sweet spot, though, the all-wheel-drive Eclipse launched with such ferocity that it could actually chirp the front fires.

From the first 0 to 60 run it was clear that the new clutch was not slipping at all. Previous runs required either you either to shift to third gear or push the engine a few hundred rpm past the redline before reaching 60 mph. With the new clutch, redline took the car all the way to 68 mph-proof that the stock clutch was slipping at several hundred rpm even in second gear!

Our best 0 to 60 run was an impressive 5.54 seconds, an improvement of almost a tenth of a second. Even more significant was the fact that while the stock clutch could only handle one good run before overheating, the Exedy clutch withstood run after run, back to back, with out ever running longer than 6 seconds. in fact, our best run was on the third attempt.

Once we found the sweet spot, though, the all-wheel drive Eclipse launched with such ferocity that it could actually Chirp the front tires.

The final test was to do some second gear pulls with the Vericom to determine our power output. This would be our first chance to finally evaluate the performance of the HRC downpipe and catalytic converter and the 550cc/min RC Engineering injectors, as well as the Exedy clutch and Road/Race flywheel, and the fine tuning work performed by Road/Race. To our great relief, peak output was up 28 horsepower. This is especially impressive when you remember that we are still using the tiny stock intercooler. The peak power reading given by our Vericorn is 210 hp, but as we discovered in our dyno comparison test several months ago (Technobabble May, 1998), the Vericom’s readings are consistent and precise, but quite a bit lower than a Dynojet. Our test of a 140-hp Sentra SE-R registered only 100 hp on the Vericom (and 117 hp on several Dynojets). Since our Eclipse’s output is 2.1 times that high, we can confidently estimate flywheel output at a bare minimum of 294 hp.

In reality, the GSX’s all-wheel drive system has to have higher driveline drag than a front wheel drive SE-R, so real flywheel output must be well over 300 hp.

We have seen this phenomenon before, but it is always interesting to see it happen. The HRC downpipe and cat, and the RC Engineering injectors obviously did their job and did it well, but simply slapping them in place and hoping for them to work won’t cut it. An engine is an amazingly complicated system and whenever you mess with one variable, you invariably will affect another one. in our case the increased air and fuel flow had to be properly adjusted to create power, and then the clutch had to be strengthened to actually harness that power. People are constantly asking us how some combination of parts will work on their car. Results like this are the reason why our answer is almost always “it depends”.