Sport Compact Car Magazine, Dec 1998

by Dave Coleman

ALL the stuff we want to do, but never did

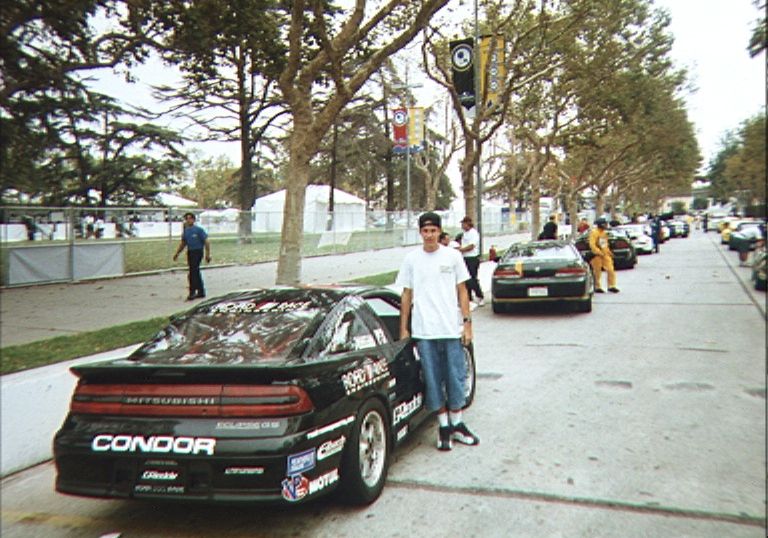

When asked by passers-by on the street what we have done to our Project Eclipse, we often settle for the short answer: “Everything.” As it comes time to say good-bye to our Eclipse GSX, though, everything just doesn’t seem like enough. While we have undeniably elevated our car’s performance to a new level, we can’t help but keep looking up for more. Our Eclipse’s last track session brought to light several of the car’s remaining weaknesses, most of which aren’t inherent weaknesses in the car at all, but problems we inflicted on the car by raising performance levels elsewhere. Following are the areas most in need of further improvement, and what we would do about it if we had the Eclipse for another year.

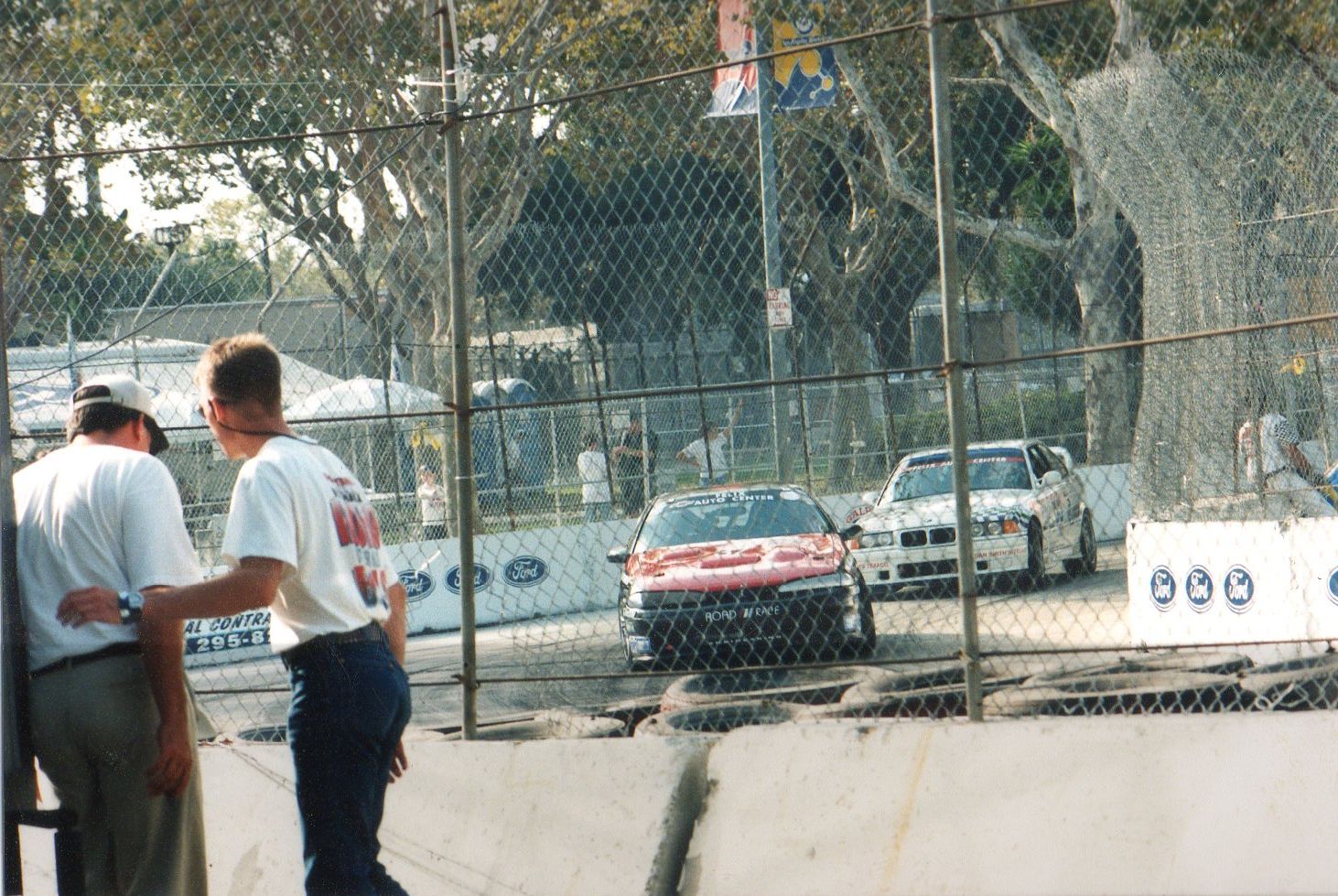

Brakes: Our quest for power was so intense that we completely neglected the brakes. As a result, we managed to destroy the front pads in the 22,000 miles that we had the car. The final sure sign that our car was under-braked for its power and weight came in the last six laps made during our last track session. It was after our photo session was done, and just after the sun had gone down. With a day’s worth of lapping under our belt, feature editor Josh Jacquot and I headed out for some last minute banzai laps to establish exactly what our Eclipse was capable of on the Streets of Willow for an upcoming story.

High beams glaring, I headed out first while Josh timed laps. After three laps pushed to the limit, I pulled in and traded keys for a stopwatch. It was then that I noticed the front rotors glowing a crimson red more stunning than the recent sunset. They reached this state after less than 3 miles of hard driving!

Josh headed out for a slow lap to cool the brakes, followed by three more laps driven in anger (Joshes laps were slightly slower than mine, of course, a fact he blames on the brakes, but which was obviously a matter of driver skill). By the end of this abuse session, the brakes’ glow was casting eerie red shadows of our Kosei wheels onto the track, and the spine-grinding metal-on-metal sound of the wear indicators dragging on the rotors accompanied the car’s every movement.

The solution? We recently drove Mitsubishi’s Eclipse Speedster show car that is essentially a mildly modified GS-T Spyder. That car was fitted with massive Baer Racing brakes up front, and 300OGT brakes in the rear. The pedal feel afforded by the massive four-piston calipers up front was another world compared to the mush of our stock brakes’ and the 13-inch rotors would surely hold up to our abuse much better than the 10.8-inch stockers. if only we could have kept the car

Alignment: The other casualty of our late night track attack was the tires. The inside edge of our 225/40-18 Dunlop SP9000s left the track looking like a cross section of the tires’ construction, with several layers of belt showing all the way around the tire. Such hard driving should have worn the outside edge of the tire, but excessive negative camber kept the inside edges overloaded The Eclipse’s double wishbone front suspension has a fairly aggressive camber curve to keep the outside tire upright while the body rolls in a turn. When we lowered the car, we not only reduced body roll by lowering the center of gravity and increasing the spring rate, we also put the suspension into a steeper part of its camber curve. The result was too much work for the inside edge of the tire, and not enough for the rest of it.

The solution? Ingalls Engineering offers a camber adjusting kit that allows you to adjust camber by up to one degree in either direction. Though not a huge range of adjustment, one degree would certainly help our problem. If only we could have kept the car..

Anti-roll bars: With all this talk of how reduced body roll contributed to our tires early demise, it may seem surprising to find anti-roll bars on our wish list. We have good reason to want them though. The Eclipse has very little suspension travel even in its stock form, and lowering the Car has only worsened the problem. While the Eibach springs and Koni shocks work well to keep the suspension off the bump stops in a straight line, body roll compresses the outside suspension, reducing the amount of travel left for soaking up imperfections in the road or track. We felt the bump stops more than once during our day at the track, and the increased cornering grip we would get from correct camber settings would only make matters worse.

Besides letting the suspension do its job, a proportionally larger rear anti-roll bar would increase the cornering burden borne by the rear suspension, thereby reducing understeer. In stock form, or with our current suspension setup, the Eclipse has a very nose-heavy cornering attitude. Getting the rear wheels to come around requires an inadvisable and unproductive amount of trail braking. The handling limits and driving enjoyment could be heightened by getting the rear wheels more involved.

The solution? Suspension Techniques is just finishing up a stiffer set of anti-roll bars for the Eclipse GSX (the GS-T set is already available) and they should be done by the time you read this. Too late for us. If only we could keep the car..

Intercooler: All of the estimated 300 hp we are making is being generated with the tiny stock intercooler. The dramatic difference between the car’s performance on a cool morning and on a hot day only serves to demonstrate how critical charge air temperature is to making power. From the beginning of the project we had planned to use a front-mounted GReddy intercooler. When it turned out that installation would require minor trimming of the front bumper and some plastic trim panels, the intercooler was ruled out.

The solution? Trim the bumper anyway! If only we could have kept the car..

ECU reprogram: Also remarkable is the fact that our estimated 300 hp is coming from the stock ECU, with adjustments for the larger injectors and increased boost being made simply by fooling the ECU with altered air mass sensor inputs from an Apex Super AFC. While this effectively moves the fuel and ignition outputs to more appropriate portions of the stock maps, it cant fix a bad map. The Eclipse ECU is full of “bad” maps, with several different fuel and ignition maps to pull from depending on how close the ECU thinks you are to damaging the engine. While this does help to keep things safe it also cripples power output.

The Solution? G-Force Engineering offered to reprogram our ECU, eliminating all those “bad” safety maps, and creating new maps more appropriate for our state of tune. To be safe, though, we wanted to tune the ECU as a last step, lest further modifications made our new map less than ideal. We neglected one simple fact, though. There’s no such thing as the last modification-there’s always more to do! if only we could have kept the car..

Interior: The last flaw on our corrective wish list is an inherent problem with the car. Tall people don’t fit. For some reason, Mitsubishi designed the interior with tons of leg room, very little head room, and no room under the steering wheel for heel-and-toe knees (similar to knobby knees, but more effective on the track). Even more problematic are seats that don’t have enough lateral support. Despite looking decidedly racy, the Eclipse’s seats are upholstered in slippery leather, and have small bolsters that are too widely spaced for the relatively narrow hindquarters of our staff. The problem is only exacerbated by the fact that our taller staffers have to lay the seat back to full cruisin’ tilt just to keep their greasy hair off the headliner.

The solution? Ever since driving Mitsubishi’s SST show car (July, 1998) we have been lusting after the Recaro seats in that car. While we may or may not be able to mount those seats any lower than the stock ones, the increased side support would at least allow us to corner without using the steering wheel as a grab handle. The other part of the solution would be a smaller steering wheel perhaps a Nardi similar to the one in the Impreza WRX-that would give our legs a little more room for heel-and-toe gyrations. If only we could… well, you get the idea.

Stock vs. Modified… An Owners Perspective

As automotive journalists, those of us at Sport Compact Car are more apt to have highly opinionated views on the cars we drive than the average car nut, After all, most of us chose this line of work because we love cars and can see merit in just about anything with four wheels. Project Eclipse seems to stir the pot of opinions here at SCC in a way that few other cars do-both good and bad. Some staffers love the car for its ultra-aggressive looks, some think it’s just too numb to ever be a real drivers car; and Others think it’s too much for the street and physically demanding. There is, however, one opinion that remains constant throughout the staff no matter who you ask This is one damn fast car!

Project Eclipse is an especially interesting endeavor for me due to the fact that for more than a year now my personal choice for transportation has been the Eclipse’s mechanically identical twin brother, a ’97 Eagle Talon TSi AWD. This gives me what I hope is a fairly unique perspective on the changes and improvements made to the car since SCC began the project in the November 1997 issue. My car is bone stock right down to the factory air box and offers a perfect test bed to make performance comparisons against Project Eclipse.

I’ll begin with drivability and horsepower improvements since these were the primary focus of the project There is almost no similarity between the results of opening the throttle on the stock car and mashing the go pedal on Project Eclipse. As noted during the car’s buildup, one of the main drawbacks in the stock car’s engine is its inability to make power beyond about 5500 rpm. This really isn’t a concern if one hasn’t driven a modified Diamond Star car-after all, they do make more than 200 hp. But after spending much quality time in Project Eclipse, the differences are too great to ignore. Don’t take this wrong, the stock car feels wonderful providing the desired turbocharged snap one expects without being peaky, just the improvement Mitsubishi wanted after the first-generation cars. Project Eclipse, at about 18 psi boost pressure, provides considerably more initial punch on spool up and will then pull hard past redline if not carefully driven. So dramatic is the improvement that it doesn’t even feel like the same power plant.

In the suspension department, the Project car is simply a more grown up version of the car I’ve come to love during the last year. Bigger wheels and tires combined with progressive-rate springs and adjustable shocks bring handling to a level not wisely explored on the street. Even the stock car will comer hard enough make one question his or her sanity, begging the driver for more throttle anywhere in a corner While the most noticeable improvement in Project Eclipse from stock is the near absence of body roll, grip is overwhelmingly improved and most noticeable at high speed despite the car’s hefty 3,157 lb weight. About the point when the stock car feels ready to lean over and touch the ground is when the Project Eclipse driver dials in more throttle.

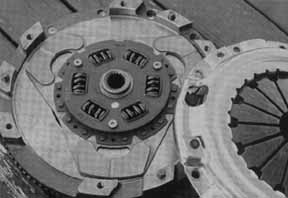

As the He-Men of modified import cars, modified Talons and Eclipses are just not easy to drive smoothly relative to others in their segment. When driven on the street the car is very much a workout. Gone are the respectable pedal feel and long, easy throws of the stock car’s controls. The most noticeable difference is certainly its high effort Exedy clutch. Having been given the privilege of driving the car during the necessary break-in period, I have to say it was not easy-especially in the inevitable Los Angeles-area traffic jams. Spending an hour with this car in traffic can be likened to going a few rounds with a Stair-master set on Mt Everest mode-difficult to say the least

That’s the great part about Project Eclipse the problems this car has when dealing with around-town driving are what make it shine on a racetrack. The high effort clutch warms tip and works wonderfully, thriving on the heat generated during aggressive driving-something the stock unit never would have survived. Even the short-throw shifter, despite its stubbornness, improves the car’s track driveability. The real drawback of the Eclipse is its overabundant bulkiness-its weight hurts braking distances and makes it much harder to manage than lighter machines.

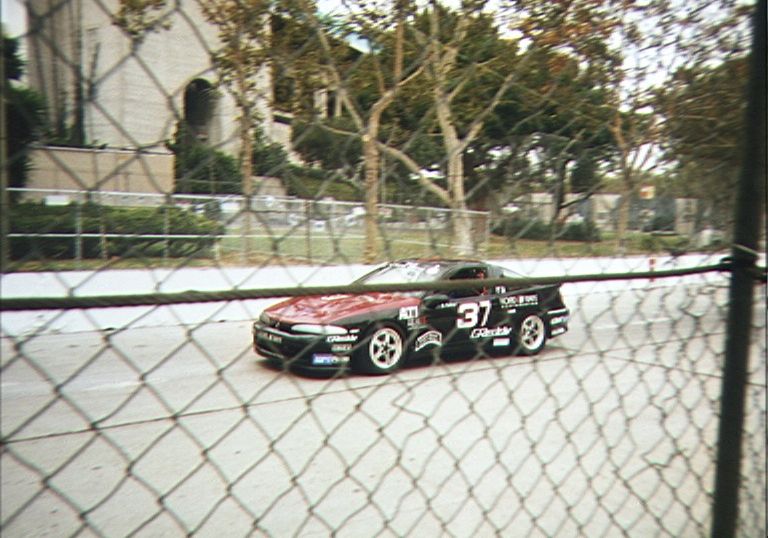

A recent day at the Streets of Willow Springs racetrack provided the necessary space to really let the car stretch its legs. My favorite trait of a stock Eclipse or Talon is it’s neutral, nearly stupid-proof nature when pushed to the limit. Project Eclipse has simply raised the limit of the stock car, taking the platform’s already good manners and making them even better. While there is no companion to be made between the power of the stock car and the project car, their handling traits are remarkably similar. Characterized by easily controlled understeer, both cars require either a major brain failure or an act of God to spin out. Get into the throttle and both cars will progressively increase understeer, back out and both come back on line. Granted, all this happens at a much higher rate of speed and g-load in the modified version. The project car can be sent slightly sideways under heavy trail braking, but rights itself instantly and comfortably to a neutral attitude before its driver can enjoy power-on oversteer. Darn it. The only way to get the stock car sideways is immediately after rain has started to fall on a greasy road surface or by going crazy in the gravel. in other words, these cats weren’t meant to be driven sideways with their open center differential.

The best part about Project Eclipse is that, despite its many mods, there is still plenty of room for improvement. It’s amazing to think that a car this capable can actually have so many areas left to improve.

Sadly, our time with Project Eclipse has come and gone. I’d like to make Mitsubishi come and peel the Eclipse keys from my fingers but luckily I’ve got its brother in my garage at home.

INSTALLMENT NO. ISSUE DATE SUBJECT

1) November, 1997 Suspension, stage I engine mods

2) January, 1998 Apex electronics (AVC-R, AFC, Turbo Timer, Boost Gauge)

3) March, 1998 Turbonetics T-28 turbo upgrade

4) September, 1998 HRC downpipe/catalyst, Road/Race fuel pump, RC injectors

5) November, 1998 Exedy clutch. fuel system tuning