Mo Boost – Nic’s 95 Talon TSi

Long time RRE customer Nic sent me a pic of his personalized Indiana license plate with the RRE plate frame on it. I asked for a little more info on the car and Nic sent me this:

Hi Mike,

Here are some pics and info on my 95 Eagle Talon TSi. Some of my mods include:

MHI Big 16G turbo

Injen Intake

Punishment Racing FMIC/piping

3” Exhaust (Apex’i Dunk cat-back)

Mishimoto Aluminum Radiator

255lph Walbro Fuel Pump

AEM Big Rotor upgrade

NGK Iridium Plugs

NGK Wires

CX Racing Fuel Pressure Regulator

H&R lowering springs

Tokico adjustable struts

NXS Manual Boost Controller

Auto Meter Phantom Gauges (A/F, Boost, Oil Temp, Oil Pressure, Water Temp)

Wings West Aggressor front bumper

Z3 Fenders

18” Nippon Racing Wheels

HKS Turbo Timer

Kenwood touch screen head unit

Optima Yellow Top battery

Custom fabricated wing

There are a few other goodies here and there, but that is the big stuff. Thanks for supporting DSMers for so many years. I’ll be rooting for the RRE team when I head down to Road Atlanta for Formula Drift next month.

Thanks,

Nic Harnishfeger

Evansville, IN

Car Feature: Jason representing DSMs in the PHX!!

Mike liked this picture of Jason’s Talon so much he asked me to set up a feature on it.

Check out the feature after the break!!

Check out the feature after the break!!

License Plate of the Week

Corey Jenson’s ’97 AWD Eclipse converted from a GS-T. He hangs with LA DSM – San Diego, CA

And runs on E-85!

2G Eclipses!

Who says the Eclipse is all played out? Walked out in the shop today and looked around… it was all 2G Eclipses getting worked on.

Araknyd – One Clean Spyder

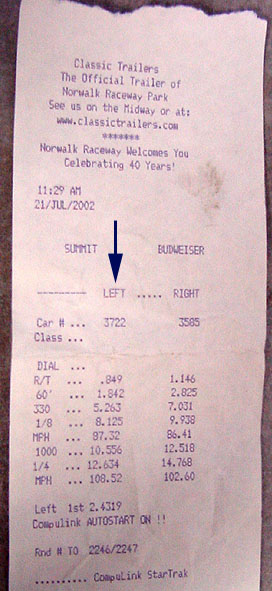

This is one of my all time favorite 2G Eclipses. Mark (Araknyd) has this crazy attention for detail and style that shows through out his 1997 Spyder GS-T. Sure it looks like a show car but it gets used as a race car too. Mark regularly drag races (1/4 mi.: 12.634 sec @ 108.52 mph, 1.84 sec 60′) and autocrosses his Spyder. Enjoy the pics!

MODIFICATIONS:

Engine/Turbo/Fuel:

- “Big” 16G Turbo

- Buschur Stage 3 Cylinder Head

- Stainless Oversized Valves

- Titanium Retainers

- HKS 264/264 Camshafts

- Fluidyne Radiator

- Stainless Braided Radiator Hoses

- RC 550cc Injectors

- Denso Fuel Pump, Upgraded Wiring

- Magnecor Plug Wires

- RRE Breather Catch Can

- A/C Removed

Intake:

- Extrude Honed 1st Gen Intake Manifold

- A’PEXi Front-Mount Intercooler

- Blitz Stainless Steel Mesh Filter

- Dejon Tools Intake Pipe (MAS to Turbo)

- RRE Custom Upper Intercooler piping

- 1st Gen Blow-off Valve

- 1st Gen Throttle Body

Exhaust:

- 3-inch cat-back made from a combination of Buschur and Thermal parts

- Victory Performance O2 housing (open dump tube for internal gate)

- RRE downpipe (2.5″ to 3″)

- 3″ high-flow catalytic converter

- Ported exhaust manifold

Drivetrain:

- Quaife Limited Slip Differential

- ACT 2600 lb. clutch

- 14.5 lb. lightened/balanced flywheel

- Shortened shifter

- Aluminum shift cable bracket bushing replacement on tranny

- “Symborski” shifter bushing modification

- Stainless steel clutch hose

- FCU (fluid containment unit) bypass

Suspension/Chassis/Interior:

- Custom 6-point roll bar by Mark McMahan

- Ground Control adjustable height coilovers (1.5″ lowered)

- Tokico Illumina 5-way adjustable shocks

- Eibach Racing Springs (500lb/300lb)

- RM Racing Stabilizer Bars

- Front strut tower brace

- RRE Lower Stress Bar

- Corbeau Forza racing seats

- Simpson Cam-lock 5-pt Harness

- SSR Competition 17×8″ wheels

- BF g-Force Drag Radials 225/45/17 (street)

- M&H Drag Slicks on Bogart 13×8 wheels (drag racing)

- Porterfield R4S brake pads

- Stainless Steel brake lines

- Prothane motor mounts

Gauges, Electronics & Controllers:

- A’PEXi S-AFC A/F Controller

- GReddy Profec B Boost Controller

- GReddy Turbo Timer

- Autometer Sport Comp Boost Gauge

- Autometer Sport Comp EGT Gauge

- Autometer Sport Comp Fuel Pressure Gauge

- Autometer Sport Comp Air/Fuel Gauge (gadgetseller.com version)

- OBDII datalogger

RRE Turbo Oil Supply Line Instructions

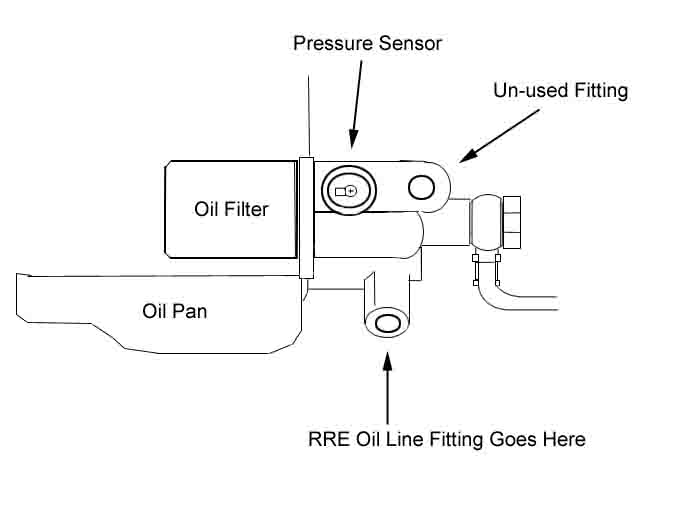

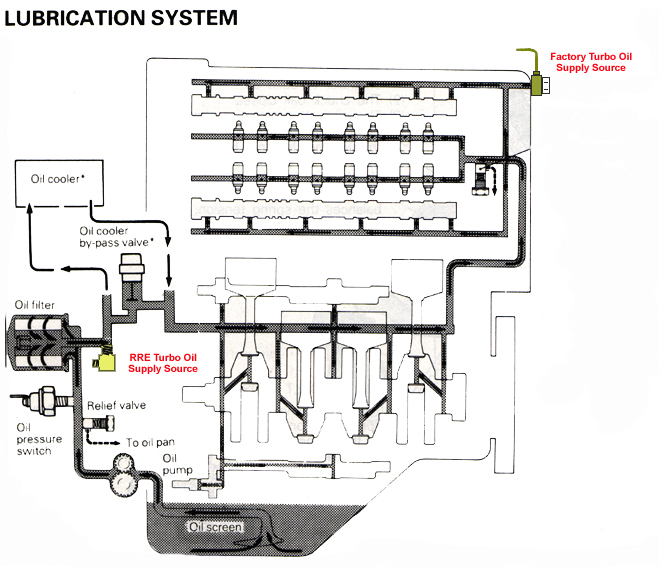

| Install the banjo bolt fitting onto the end of the -4 stainless line and tighten the fitting before bolting the banjo fitting to the turbo. Install the assembled oil supply line to the turbo before installing theturbo onto the manifold. Use new copper crush washers and torque the banjo bolt to about 25 foot pounds.1G: Remove the correct Allen plug from the oil filter housing. See the photos below for the correct location !If the Allen plug is tight and you think that you might strip out the Allen socket, heat will loosen it. The heat allows the aluminum housing to expand and loosen it’s grip on the plug. Heat also loosens any thread sealant. Get it warm with a propane torch or oxy/acetylene torch. Don’t melt anything, just warm it up good. If you strip out the Allen fitting to the point that an Allen wrench wont turn it, you are screwed.2G: Remove the larger fitting and replace it with the 90 degree fitting.Use thread sealant or Teflon tape on the pipe threads that screw into the housing. Note that the threads are cut into the housing at a different angle than the face of the housing. It will almost look like it is threading into the housing crooked. Be careful with any sealant or tape, you do not want anything to get into the turbo bearings.If you find that the clearance to the oil pressure sensor is too close to the fitting to screw it in, remove the sensor, install the 90 degree fitting and re-install the sensor.

2G Connected at the turbo Oil supply location on a 2G Note that the fitting screws into the housing hole at a slight angle to the machined face. This can seem a little odd when first getting the threads started. Note the angle of the stock adapter fitting before you remove it, this will help. The fitting threads are a tapered pipe thread, as you screw it in, it will get tighter. Be sure to stop at a clocking that will allow the proper run of the oil line. Tied off to the fan shroud. Tied off to the fan shroud. Don’t let the line contact the fan shroud directly. We use a double zip tie to separate them. 1G If you specified the oil supply line for a 1G, use the supplied short 10mmx1.25 bolt and crush washer to block off the stockoil supply location at the cylinder head. Oil supply location on a 91-94 1G Turbo 91-94 1G supply location pictured. You want the upper and outer fitting location. Using the lower fitting on a ’91-94 oil filter housing (water cooled oil cooler) will result in the turbo receiving unfiltered oil. 90 1G supply location pictured. On a 90 model oil filter housing, the two fittings are spread out a little more. Use the lower fitting on a ’90 oil filter housing (cars with a factory air cooled oil cooler). Using the upper outer fitting will give unfiltered oil to the turbo. Stock, the turbo oil supply is just about the last oil in the whole motor. If you get it at the oil filter housing, you get oil fresh out of the filter. Note that if you do not use the specified location, you will be using unfiltered oil. |

RRE 2G Eclipse SS Clutch Line Instructions

2G Turbo Cars (95-99)

The RRE SS Clutch line replaces the Rubber flexible line that runs from the frame rail under the fuse box down to the transmission. On a 2G car, it also replaces the reservoir that is bolted to the front of the transmission.

Unbolt the fuse box so that is can be shifted to the side. Crack loose the 10mm flare nut to the stock hose. After it is cracked loose then remove the clip that secures the hose end to the bracket with pliers. Unbolt the reservoir from the transmission by removing the 3 12mm head bolts. Remove the banjo bolt to the slave cylinder.

Here is a pic of the stock hose / reservoir / line assembly once it is removed.

Install the new line using the supplied banjo bolt and new crush washers. You will need to bleed the clutch fluid of all air in the lines. Use any brake fluid for the clutch hydraulic fluid. Check for leaks.

When installing the SS Clutch line, you have the option of removing the clutch fluid restrictor. It is a small plate with a .050″ hole in it that slows down the release of the clutch. Mitsubishi put it in there to help make clutch release smooth and slow. If you want it to release faster than you have now, pull it out. Our suggestion is to try your clutch with just the new line first. If you want more grab than that, pull the restrictor too, just be careful what you wish for.

This is a pic of the restrictor being picked out of the hole once the banjo bolt has been removed.

This is the restrictor once it is removed

While you are down there replacing the clutch line, also check to see if the slave cylinder is leaking. Pull back the rubber boot. There should be NO fluid in there. If there is fluid behind the boot, it is leaking past the piston and seal. Most 1G cars and many higher mileage 2G cars will have this problem.

Roy’s Bad Day

Roy had a walking crankshaft a few months ago. The short block was replaced at the dealership under warranty. A few months later driving on the freeway (minding his bidness)… ka boom. No warning, thought he ran over a bumper.

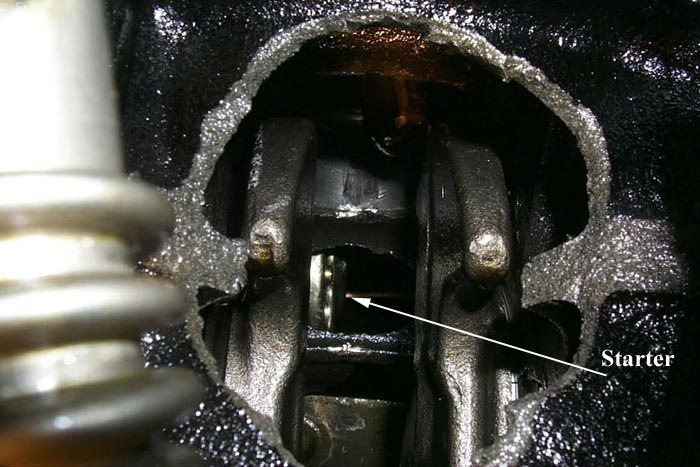

The rod nuts on #3 backed all the way off, and the crankshaft punted the rod out the block. Out of the park home run. View from the front of the motor, looking through at the starter:

The shrapnel made holes in both sides of the block. That is Jacks finger behind the motor at the starter.

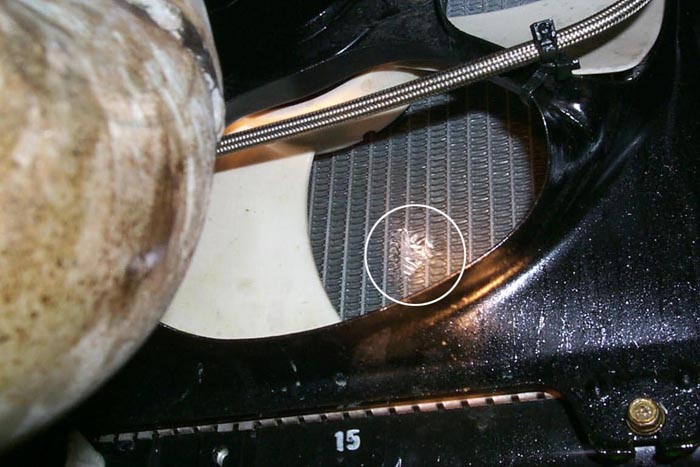

The front chunk of engine block ricocheted off the turbo oil drain tube and made a hole in the radiator.

The oil pan, ouch.

The rod. No discoloration from a bad bearing. Note the missing rod bolts. Gone clean.

The coolest part. In the explosion and ensuing aftermath, there must have been quite a fireball under the car. All the paint is burned off the lower back bumper cover. Even up by the license plate light the paint is blistered. Must have been a sight to be following him.

Back to the dealer for some more warranty work.

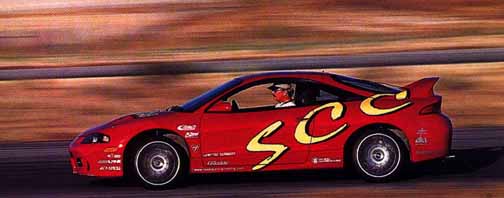

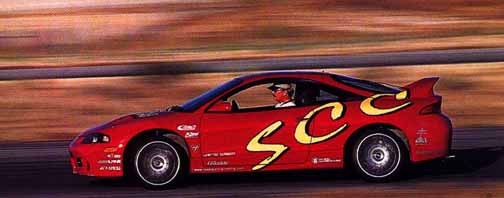

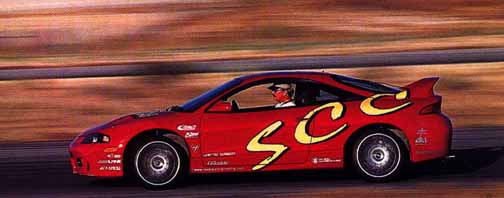

SCC Magazine Eclipse Project – MORE OF EVERYTHING

Sport Compact Car Magazine, Dec 1998

by Dave Coleman

ALL the stuff we want to do, but never did

When asked by passers-by on the street what we have done to our Project Eclipse, we often settle for the short answer: “Everything.” As it comes time to say good-bye to our Eclipse GSX, though, everything just doesn’t seem like enough. While we have undeniably elevated our car’s performance to a new level, we can’t help but keep looking up for more. Our Eclipse’s last track session brought to light several of the car’s remaining weaknesses, most of which aren’t inherent weaknesses in the car at all, but problems we inflicted on the car by raising performance levels elsewhere. Following are the areas most in need of further improvement, and what we would do about it if we had the Eclipse for another year.

Brakes: Our quest for power was so intense that we completely neglected the brakes. As a result, we managed to destroy the front pads in the 22,000 miles that we had the car. The final sure sign that our car was under-braked for its power and weight came in the last six laps made during our last track session. It was after our photo session was done, and just after the sun had gone down. With a day’s worth of lapping under our belt, feature editor Josh Jacquot and I headed out for some last minute banzai laps to establish exactly what our Eclipse was capable of on the Streets of Willow for an upcoming story.

High beams glaring, I headed out first while Josh timed laps. After three laps pushed to the limit, I pulled in and traded keys for a stopwatch. It was then that I noticed the front rotors glowing a crimson red more stunning than the recent sunset. They reached this state after less than 3 miles of hard driving!

Josh headed out for a slow lap to cool the brakes, followed by three more laps driven in anger (Joshes laps were slightly slower than mine, of course, a fact he blames on the brakes, but which was obviously a matter of driver skill). By the end of this abuse session, the brakes’ glow was casting eerie red shadows of our Kosei wheels onto the track, and the spine-grinding metal-on-metal sound of the wear indicators dragging on the rotors accompanied the car’s every movement.

The solution? We recently drove Mitsubishi’s Eclipse Speedster show car that is essentially a mildly modified GS-T Spyder. That car was fitted with massive Baer Racing brakes up front, and 300OGT brakes in the rear. The pedal feel afforded by the massive four-piston calipers up front was another world compared to the mush of our stock brakes’ and the 13-inch rotors would surely hold up to our abuse much better than the 10.8-inch stockers. if only we could have kept the car

Alignment: The other casualty of our late night track attack was the tires. The inside edge of our 225/40-18 Dunlop SP9000s left the track looking like a cross section of the tires’ construction, with several layers of belt showing all the way around the tire. Such hard driving should have worn the outside edge of the tire, but excessive negative camber kept the inside edges overloaded The Eclipse’s double wishbone front suspension has a fairly aggressive camber curve to keep the outside tire upright while the body rolls in a turn. When we lowered the car, we not only reduced body roll by lowering the center of gravity and increasing the spring rate, we also put the suspension into a steeper part of its camber curve. The result was too much work for the inside edge of the tire, and not enough for the rest of it.

The solution? Ingalls Engineering offers a camber adjusting kit that allows you to adjust camber by up to one degree in either direction. Though not a huge range of adjustment, one degree would certainly help our problem. If only we could have kept the car..

Anti-roll bars: With all this talk of how reduced body roll contributed to our tires early demise, it may seem surprising to find anti-roll bars on our wish list. We have good reason to want them though. The Eclipse has very little suspension travel even in its stock form, and lowering the Car has only worsened the problem. While the Eibach springs and Koni shocks work well to keep the suspension off the bump stops in a straight line, body roll compresses the outside suspension, reducing the amount of travel left for soaking up imperfections in the road or track. We felt the bump stops more than once during our day at the track, and the increased cornering grip we would get from correct camber settings would only make matters worse.

Besides letting the suspension do its job, a proportionally larger rear anti-roll bar would increase the cornering burden borne by the rear suspension, thereby reducing understeer. In stock form, or with our current suspension setup, the Eclipse has a very nose-heavy cornering attitude. Getting the rear wheels to come around requires an inadvisable and unproductive amount of trail braking. The handling limits and driving enjoyment could be heightened by getting the rear wheels more involved.

The solution? Suspension Techniques is just finishing up a stiffer set of anti-roll bars for the Eclipse GSX (the GS-T set is already available) and they should be done by the time you read this. Too late for us. If only we could keep the car..

Intercooler: All of the estimated 300 hp we are making is being generated with the tiny stock intercooler. The dramatic difference between the car’s performance on a cool morning and on a hot day only serves to demonstrate how critical charge air temperature is to making power. From the beginning of the project we had planned to use a front-mounted GReddy intercooler. When it turned out that installation would require minor trimming of the front bumper and some plastic trim panels, the intercooler was ruled out.

The solution? Trim the bumper anyway! If only we could have kept the car..

ECU reprogram: Also remarkable is the fact that our estimated 300 hp is coming from the stock ECU, with adjustments for the larger injectors and increased boost being made simply by fooling the ECU with altered air mass sensor inputs from an Apex Super AFC. While this effectively moves the fuel and ignition outputs to more appropriate portions of the stock maps, it cant fix a bad map. The Eclipse ECU is full of “bad” maps, with several different fuel and ignition maps to pull from depending on how close the ECU thinks you are to damaging the engine. While this does help to keep things safe it also cripples power output.

The Solution? G-Force Engineering offered to reprogram our ECU, eliminating all those “bad” safety maps, and creating new maps more appropriate for our state of tune. To be safe, though, we wanted to tune the ECU as a last step, lest further modifications made our new map less than ideal. We neglected one simple fact, though. There’s no such thing as the last modification-there’s always more to do! if only we could have kept the car..

Interior: The last flaw on our corrective wish list is an inherent problem with the car. Tall people don’t fit. For some reason, Mitsubishi designed the interior with tons of leg room, very little head room, and no room under the steering wheel for heel-and-toe knees (similar to knobby knees, but more effective on the track). Even more problematic are seats that don’t have enough lateral support. Despite looking decidedly racy, the Eclipse’s seats are upholstered in slippery leather, and have small bolsters that are too widely spaced for the relatively narrow hindquarters of our staff. The problem is only exacerbated by the fact that our taller staffers have to lay the seat back to full cruisin’ tilt just to keep their greasy hair off the headliner.

The solution? Ever since driving Mitsubishi’s SST show car (July, 1998) we have been lusting after the Recaro seats in that car. While we may or may not be able to mount those seats any lower than the stock ones, the increased side support would at least allow us to corner without using the steering wheel as a grab handle. The other part of the solution would be a smaller steering wheel perhaps a Nardi similar to the one in the Impreza WRX-that would give our legs a little more room for heel-and-toe gyrations. If only we could… well, you get the idea.

Stock vs. Modified… An Owners Perspective

As automotive journalists, those of us at Sport Compact Car are more apt to have highly opinionated views on the cars we drive than the average car nut, After all, most of us chose this line of work because we love cars and can see merit in just about anything with four wheels. Project Eclipse seems to stir the pot of opinions here at SCC in a way that few other cars do-both good and bad. Some staffers love the car for its ultra-aggressive looks, some think it’s just too numb to ever be a real drivers car; and Others think it’s too much for the street and physically demanding. There is, however, one opinion that remains constant throughout the staff no matter who you ask This is one damn fast car!

Project Eclipse is an especially interesting endeavor for me due to the fact that for more than a year now my personal choice for transportation has been the Eclipse’s mechanically identical twin brother, a ’97 Eagle Talon TSi AWD. This gives me what I hope is a fairly unique perspective on the changes and improvements made to the car since SCC began the project in the November 1997 issue. My car is bone stock right down to the factory air box and offers a perfect test bed to make performance comparisons against Project Eclipse.

I’ll begin with drivability and horsepower improvements since these were the primary focus of the project There is almost no similarity between the results of opening the throttle on the stock car and mashing the go pedal on Project Eclipse. As noted during the car’s buildup, one of the main drawbacks in the stock car’s engine is its inability to make power beyond about 5500 rpm. This really isn’t a concern if one hasn’t driven a modified Diamond Star car-after all, they do make more than 200 hp. But after spending much quality time in Project Eclipse, the differences are too great to ignore. Don’t take this wrong, the stock car feels wonderful providing the desired turbocharged snap one expects without being peaky, just the improvement Mitsubishi wanted after the first-generation cars. Project Eclipse, at about 18 psi boost pressure, provides considerably more initial punch on spool up and will then pull hard past redline if not carefully driven. So dramatic is the improvement that it doesn’t even feel like the same power plant.

In the suspension department, the Project car is simply a more grown up version of the car I’ve come to love during the last year. Bigger wheels and tires combined with progressive-rate springs and adjustable shocks bring handling to a level not wisely explored on the street. Even the stock car will comer hard enough make one question his or her sanity, begging the driver for more throttle anywhere in a corner While the most noticeable improvement in Project Eclipse from stock is the near absence of body roll, grip is overwhelmingly improved and most noticeable at high speed despite the car’s hefty 3,157 lb weight. About the point when the stock car feels ready to lean over and touch the ground is when the Project Eclipse driver dials in more throttle.

As the He-Men of modified import cars, modified Talons and Eclipses are just not easy to drive smoothly relative to others in their segment. When driven on the street the car is very much a workout. Gone are the respectable pedal feel and long, easy throws of the stock car’s controls. The most noticeable difference is certainly its high effort Exedy clutch. Having been given the privilege of driving the car during the necessary break-in period, I have to say it was not easy-especially in the inevitable Los Angeles-area traffic jams. Spending an hour with this car in traffic can be likened to going a few rounds with a Stair-master set on Mt Everest mode-difficult to say the least

That’s the great part about Project Eclipse the problems this car has when dealing with around-town driving are what make it shine on a racetrack. The high effort clutch warms tip and works wonderfully, thriving on the heat generated during aggressive driving-something the stock unit never would have survived. Even the short-throw shifter, despite its stubbornness, improves the car’s track driveability. The real drawback of the Eclipse is its overabundant bulkiness-its weight hurts braking distances and makes it much harder to manage than lighter machines.

A recent day at the Streets of Willow Springs racetrack provided the necessary space to really let the car stretch its legs. My favorite trait of a stock Eclipse or Talon is it’s neutral, nearly stupid-proof nature when pushed to the limit. Project Eclipse has simply raised the limit of the stock car, taking the platform’s already good manners and making them even better. While there is no companion to be made between the power of the stock car and the project car, their handling traits are remarkably similar. Characterized by easily controlled understeer, both cars require either a major brain failure or an act of God to spin out. Get into the throttle and both cars will progressively increase understeer, back out and both come back on line. Granted, all this happens at a much higher rate of speed and g-load in the modified version. The project car can be sent slightly sideways under heavy trail braking, but rights itself instantly and comfortably to a neutral attitude before its driver can enjoy power-on oversteer. Darn it. The only way to get the stock car sideways is immediately after rain has started to fall on a greasy road surface or by going crazy in the gravel. in other words, these cats weren’t meant to be driven sideways with their open center differential.

The best part about Project Eclipse is that, despite its many mods, there is still plenty of room for improvement. It’s amazing to think that a car this capable can actually have so many areas left to improve.

Sadly, our time with Project Eclipse has come and gone. I’d like to make Mitsubishi come and peel the Eclipse keys from my fingers but luckily I’ve got its brother in my garage at home.

INSTALLMENT NO. ISSUE DATE SUBJECT

1) November, 1997 Suspension, stage I engine mods

2) January, 1998 Apex electronics (AVC-R, AFC, Turbo Timer, Boost Gauge)

3) March, 1998 Turbonetics T-28 turbo upgrade

4) September, 1998 HRC downpipe/catalyst, Road/Race fuel pump, RC injectors

5) November, 1998 Exedy clutch. fuel system tuning

SCC Magazine Project Eclipse – Final

Mitsubishi Eclipse GSX Part Six

Time To Say Goodbye

By Kieth Buglewicz

Reprinted with Permission

It’s not like we didn’t know it was going to happen, It never really belonged to us, despite how close we had gotten to the car. No, our long-term Mitsubishi Eclipse was ultimately, a short timer. But in the year (plus 3 months, thanks to Mitsubishi’s benevolent PR king Kim Custer) we had the car, we had more fun than is probably legal, were able to cram a good amount of performance under the hood, and discovered at the end that it, indeed, all work as advertised.

This speaks volumes for the versatility and flexibility of Mitsubishi’s 2.0 liter turbocharged four cylinder. But despite our efforts, we could have done more. The brakes were still stock. The engine itself had never been opened, so there was room for porting and polishing. The car desperately needed an upgraded intercooler. The list goes on practically forever, and you can see what else we would have done if we could have kept the car longer by checking out Dave Coleman’s sidebar.

Rather than express a wish list, I’m here to recap what we have done, and try to keep emotion out of it.

We got the Eclipse in May of 1997 with a scant 26 miles on it. It was, however, a case of the third time being charmed, as we had gone through two other cars previously. Our first car was virtually identical (it had a brown interior) and was pulled from Mitsubishi’s press pool. However, after a week with the car, an ugly problem reared its head: The transmission was making horrendous gronking sounds in first gear at full throttle. We returned the car, and were told it was actually a pre-production vehicle that had already had the transmission replaced. We were asked if we would like a brand-new car built especially for us at Mitsubishi’s Normal, 111. plant. Not being stupid, we said yes.

After a week . . . The transmission was making horrendous gronking sounds in first gear at full throttle.

The second car we never actually saw. After about a month of waiting (not unusual for a special order), it showed up in April. We got the call from Steve Kosowski (also of Mitsubishi PR) that our new baby was delivered…but there was another problem. Somewhere, somehow, despite the fact that Steve wrote on the order form that we wanted a five-speed manual transmission (he showed us the form), the car arrived with an automatic. Crap.

Since, as everyone knows, an automatic transmission in a car like the Eclipse would be just as useful as training wheels, we agreed with Steve’s suggestion that the plant build us another car. One month later, it arrived. Steve told us it wasn’t quite to spec either, as it had a gray interior rather than a brown and black one. Gray, brown, black, lavender…as long as all the big mechanical bits were in place, we were happy.

It didn’t take long for us to break in the car After an oil change at 500 miles, and another at 1,000, we were ready to play. One thing had become apparent to us almost immediately: If we had looked at the order form more carefully, we would have skipped the sunroof. This is advice anyone over about 5 feet 11 inches tall should take to heart. The seating position was also uncomfortable for tall people because of the low slung steering wheel. Even at its uppermost adjustment, it was in the way Incidentally, aside from amputees, I can’t imagine who would set the wheel at its lowest setting; the wheel almost completely blocks access to the pedals.

Despite having to adjust ourselves to sit in the car, we were impressed by its power and grip. But the break-in period also allowed us to determine our first course of action. One of the first things that drew attention to itself was the suspension. The Eclipse is no light weight ours weighed in at more than 3,500 lbs with two people on board but its strong motor makes up for it by yanking the car around at a good clip. The suspension is stiff enough to stick the car in a turn, but soft enough to let the heavy body gently bob up and down on fast sweepers. You never feel like the car is going to fly out of control, but the feeling is a little unsettling. We decided to upgrade not just the springs, but the shocks as well to give us the handling we wanted. We opted for Eibach’s Pro Kit springs along with Koni’s s adjustable shocks.

Not only did the suspension mods work, but the incremental lowering job (only about an inch all around) hunkered the car closer to the ground, making it look like a badger: Low, wide, and always angry about something. Naturally, the suspension mods made the car much more capable than its stock tires (lackluster Goodyears) could handle. So we upgraded to 225/40ZR18 Dunlop SP9000 tires. They proved to be a good choice, with very good dry grip and virtually untouchable wet grip. Coupled with the all-wheel drive character of the Eclipse, this was one sports car that was unafraid of the rain.

The second thing we noticed about the car in its stock form was that after an initial surge of boost, power would start to fall off at about 5500 rpm. Frankly, revving the engine to its 7000 rpm redline was fruitless: The engine only produced noise after about 6200 rpm One glance at the engine bay and it was clear the anemic stock intake and exhaust were to blame. We installed a HKS cat-back exhaust system, which produced the expected exhaust note for an Eclipse: A loud farting blat. On the intake side, we installed a K&N intake, a GReddy blow-off valve, and a Road/Race Engineering intercooler pipe.

Mike Welch at Road/Race is well known in the Eclipse community as a guy who seems to have an unhealthy amount of knowledge about these cars. If he could, I’m sure he’d sleep with one under his pillow. But that knowledge made him our unofficial Project Eclipse Performance Guru, and we turned to him for just about every question we wanted answered. Opening up the intake was his first suggestion, and he let us in on a secret that is often overlooked. The stock blow-off valve feeds back into the intake pipe. This keeps the computer happy, since it has already measured that air with the air mass sensor. To keep noise levels down though, the blow off valve dumps into a four-inch long dump pipe that extends far down into the intake hose.

Not only did the suspension mods work, but the lowering job (only about an inch all around) hunkered the car closer to the ground, making it look low, wide, and always angry

What this means is that although the intake pipe looks big from outside, it is significantly blocked by the dump pipe. Mike’s solution to this intake blockage is simple: Cut the return pipe out. It doesn’t actually make a lot of power, but it adds to the responsiveness of the engine. The gains were immediately apparent. The car built boost much more quickly and held it much longer, making power almost all the way to redline.

Mike’s solution to this intake blockage is simple: Cut the return pipe out. It doesn’t actually make a lot of power, but it adds to the responsiveness of the engine

Making performance modifications to our car presented us with the problem of quantification. We needed to demonstrate that our Eclipse felt faster because it was, not because we could hear the whoosh of the turbo and the flatulent exhaust note more clearly after our mods. Luckily, we had a solution to getting “dyno” results from our Eclipse in the form of our Vericom 2000 performance computer.

In an oversimplification, the Vericom is essentially an accelerometer. By measuring how quickly a car accelerates in a certain gear, then plugging in weight, ambient air temperature and other factors, one can calculate how much power the car is making. The results were consistent enough for us to publish, as long as we tested back to back each time (the Vericom turned out significant fluctuations depending on air temperature). The result was a solid 30-hp increase for slightly less than $1,000 worth of parts that would be easy to install for even a mediocre mechanic.

Naturally, we wanted more power. So we decided to turn up the wick with more boost. This produced cries of “You’re gonna kill it!” from our photo editor, Les Bidrawn. Multiple assurances couldn’t dissuade him: He was certain we were about to murder our car.

Flush with our early success, we figured that just by wiring in an Apex boost controller and fuel computer, turning the boost up to about 17 psi and hitting the streets, we’d be flying fast. And we were right, to a certain extent. The boost controller fattened the midrange power significantly, but was unable to hold boost very long after about 5000 rpm. We had run up against another wall, although far earlier than we had anticipated. We turned to Road/Race for an answer.

The stock turbo, as it turns out, is barely adequate for the stock engine’s needs. Although the Eclipse is rated at a peak boost of 14 psi, it holds this only for a few hundred rpm before boost falls off to about 9 psi by redline. Part of the problem is with the crummy stock blow off valve, which has virtually no method of sealing against its seat, and has a spring so weak it can be pushed down with your pinkie. We replaced that in step one, but still had boost problems. We thought that by adding a boost controller, we would be able to hold boost to redline.

In the mean time, we had moved the Apex turbo timer, fuel computer and boost controller to the center console. Although the stock stereo sounded great, it was removed for our surgery. Replacing it was an Alpine three disc in-dash CD changer. The sound was great, and the unit was loaded with features. Competition Soundworks in Cerritos, Calif. did the installation work, and we undertook mounting the Apex gear under the Alpine unit ourselves. The result looked great, and was much more ergonomic.

The next step in our upgrade was the most drastic. Most Honda and Acura drivers would suggest the very popular T3/T4 hybrid turbo. However, that particular turbo requires significant heat shielding to prevent it from melting the air conditioner fan. Instead, Turbonetics in Moorpark, Calif., set us up with an upgraded version of the stock turbo. Since we were only planning to run about 18 psi of boost, the modified stock turbo would be more than adequate. We also had a couple other concerns, mainly that the car was driven daily, and we wanted a turbo that would give us the power we wanted without excessive lag. We also wanted something that would be reliable, for the same reason. Longevity was the key, and since the car did eventually have to go back to Mitsubishi, we wanted to return a working automobile, not a car-shaped pile of non-working parts.

Turbonetics modified the turbine and compressor housing of a stock Eclipse turbo to accommodate larger wheels. This in turn allowed the turbo to flow more than 30 percent more air without significantly increasing lag, an advantage we probably would not have had if we went to a physically larger unit. We once again turned to Road/Race Engineering for installation, where Mike had a suggestion for improving flow. A ported exhaust manifold, he said, would significantly aid flow to the turbine, as would porting the huge cast iron exhaust flange from the turbo to the exhaust down pipe. The result was much snappier throttle response, gobs of midrange power, and virtually no lag whatsoever.

But the high end was still falling off boost, regardless of the new turbo. One culprit we thought might be to blame was the fuel system. After we installed the turbo, the fuel cutout would abruptly shut off the fun in cool weather (when the intake charge was most dense). The car felt like it hit a wall each time it happened, and also made the check engine light come on for the first time (it also had us wondering if, after all, Les had been right). To cure the problem, we installed a set of 550 cc injectors from RC Engineering next, as well as a higher capacity fuel pump and exhaust gas temperature gauge to properly calibrate the Apex fuel computer. We also installed a 3inch stainless steel, mandrel bent downpipe from Hahn Racecraft and a 3-inch catalytic converter to remove the final obstructions from our exhaust system.

We once again succeeded in improving mid-range output, with another incremental gain at the high end. But at last, we found why top end power had been so elusive. While he was tuning the fuel compute; Mike Welch noticed that as he data-logged speed and rpm, the two would increase at the same rate (as they should) through the middle of the rev range, but at high rpm the engine would start accelerating faster than the car! There was only one answer: The stock clutch was being overwhelmed at high engine speeds when the turbo was at full song. The fix came in the form of a three-puck Exedy clutch.

Flush with our early success, we figured that just by with In an Apex boost controller and fuel computer, turning the boost up to about 17 psi and hit the streets, we’d be flying fast. And we were right, to a certain extent

Man, did it work. Finally, the top end acceleration matched the low- and mid-range surge. The engine held boost now to redline, and the car felt like we had installed an afterburner instead of a clutch. No sooner was the clutch installed than we took the car to the Streets of Willow at Willow Springs Raceway in Rosamond, Calif., for a little testing. The new clutch demanded respect, requiring good matching of revs at every shift to avoid a lurch when the clutch grabbed…and grabbed hard. But driven even moderately well, the Eclipse screamed around the track. Far from lithe and nimble, the GSX felt like it made its way around the track by getting the pavement in a death grip and bullying its way through the laws of physics. Driven full bore, the Eclipse could dive into each corner with the ABS pulsing like mad, fight its way to the apex, and then spit the corner out behind under full boost. Powering out of the corner was always the most difficult part, as terminal understeer was often the result when a surge of boost felt like it was lifting the front wheels and pushing them sideways. Extreme understeer would make the out side front tire chatter across the pavement a very unsettling feeling but if you balanced steering input correctly on the exit, the Eclipse was extremely fast. Of course, all this brute force did take its toll on the brakes and tires, but it sure was fun!

Far from lithe and nimble, the GSX felt like it made its way around the track by getting the pavement in a death grip and bullying its way through the laws of Physics

Which more or less brings us to where we are today, returning the car to Mitsubishi. During its time with us. The Eclipse appeared at numerous event, including the 1997 SEMA show in Las Vegas, the 1998 SEMA Import Auto Salon and the 1998 Long Beach Grand Prix. Not to mention the numerous local drag races and car shows. With its wild graphics scheme (courtesy of Imagine It Graphics), the Eclipse excelled at attracting attention. Which, of course, was sort of the whole point.

So, we bid farewell to the Eclipse, impressed with its performance potential and with the fact that nothing ever broke, despite everything we threw at it (a worn clutch doesn’t count). What the future holds for Mitsubishi’s sporty coupe is truly unknown at this time. We’ve heard rumors that the turbocharged 2.0-liter motor will disappear with this particular model, replaced by the new 3.0-liter V6 found in the ’99 Galant. With 195 horsepower, this would not necessarily be a bad thing. On the other hand, we’ve also heard that the turbo motor may make a return. You can expect all wheel drive to bid a final farewell: Mitsubishi sells very few turbocharged models, and even fewer GSXs.

| What it Cost | |

| Suspension | |

| Springs: Eibach Pro Kit | $225 |

| Shocks: Koni | $576 (set of 4) |

| Wheels: Kosei Seneca 18 x 8 in. | $420 (each) |

| Tires: Dunlop SP9000 225/40ZR18 | $228 (each Tire Rack Price) |

| Engine | |

| Exhaust: HKS | $480 |

| Turbocharger Turbonetics T28 upgrade | $850 |

| Intercooler Pipe: Road///Race | S90 |

| Blow-Off Valve: GReddy Type S | $205 |

| Intake: K&N | $95 |

| Fuel Computer: Apex Super AFC | $369 |

| Turbo Timer: Apex | $99 |

| Boost Controller: Apex | $579 |

| Sound System: | |

| 3-disc in dash head unit: Alpine 3DE-7886 | $480 |

| Speakers: Alpine SPS-1326 | $80 |

| INTERIOR: | |

| Short Shifter: Pace Setter | $190 |

| Shift Knob: RAZO | $85 |

| Pedal Pads: RAZO | $77 |

| EGT Gage: Apex` | $211 |

| Boost Gage: Apex | $170 |

SCC Magazine – Project Eclipse – Interior Mods

Focus On The Cockpit

Sport Compact Car Magazine November 1998

By Dave Coleman

Over the last several months we have made several improvements to the Eclipse’s driving environment, most of which were overshadowed by out quest for power. The earliest change we made was to accommodate the Apex electronics we installed in our second update on the car (Project Eclipse GSX, January, 1998). Initially we had simply taped the Super AFC, AVC-R boost controller, and turbo timer to the underside of The dash. This only worked for about four hours, however, before we had to contend with electronic devices dropping onto our feet every few minutes when the tape let go. We wanted to mount all three devices in the dash, but with the double-DIN sized factory stereo/CD/cassette deck taking Lip all the room, there was nowhere for them to go.

The stock stereo took up too much room for our new electronics so it had

While the factory stereo is actually quite good, it was in the way. If we installed a standard, single-DIN unit, there would be plenty of room to mount our electronics, but we would have to give up some features of the factory stereo to make it work. It wasn’t a very hard decision, as we never used the cassette portion of the stereo. The change would also allow, I us to take advantage of some better audio options.

Competition Soundworks cut adapters to mount the Alpine speakers in the stock door locations.

An extra stereo mounting frame was used to mount the Apex electronics, To fit the frame below the stereo, we had to cut the lip off the top of it. We used a air-powered cutting wheel, but if you don’t have one you’ll just have to get creative. The meat is relatively thin and easily cut.

Since the Eclipse didn’t have a CD changer, and we often end up driving the car long distances to events, we decided to go with Alpine’s 3DE-7886 three-disc in dash CD changer. it turned out to be a good choice. The amplified unit (35Wx4 channels) gave us good CD selection without eating up a bunch of cargo space with a changer (those long trips mean a lot of luggage in the Eclipse’s surprisingly large cargo space). And the unit was packed with enough features to keep even the most ardent gadget hound occupied for hours. Things like programmable preset address indicator, station title memory and automatic memory programming for the tuner, with 8X oversampling, a 1 bit DA converter, disc title memory and a host of other features we never, got to explore. We had Competition Soundworks in Cerritos Calif. install the CD Changer and a set of Alpine speakers in the doors.

The Apex boxes were hot glued into the frame before being inserted into the dash.

We wanted to mount all three devices in the dash, big with the double-DIN sized factory stereo/CD/cassette deck taking. up all the room there was nowhere for them to go

To fill the hole left next to the AFC, we bent up a sheet metal block off plate,

We then peeled the Apex plaque off the top of the turbo timer and mounted it on the block-off plate.

The new arrangement was definitely worth the work. The installation looks clean and well organized, and the Alpine stereo sounds great!

The CD changer was mounted in the top half of the double DIN hole to allow the CD cassette to shuffle without interfering with the shifter To mount the Apex electronics we used an extra mounting frame. Both the turbo timer and the AVC-R boost controller are quarter DIN sized, while the AFC is slightly wider. We could fit all three boxes in a single DIN slot with a small gap left next to the AFC. To mount each box, we simply used a hot glue gun to stick it to the frame, while the gap was filled with a sheet metal panel we cut out, and decorated with an Apex emblem we peeled off the top of the boost controller.

The Pace Setter shifter shortens shift throws by at shortening the rod above the pivot, and lengthening the rod below the pivot point,

Accessing the shifter can be difficult if you don’t know where to start. The first step is to remove the ash tray, there are some hidden mounting screws for the center console under here.

On other interior notes, the Eclipse’s cable shifter is rather clunky and imprecise. It also has a relatively long throw that makes fast shifting a little difficult. In an effort to solve this problem we installed a short shifter from Pace Setter. The short shifter both lowers the shift knob and changes the lever ratio between your hand and the shifting cables. This both shortens the shift throw and increases shifting effort. The shorter throws are definitely an improvement, but the increased effort makes shifting even more difficult. The shifter didn’t really feel any more precise-,,, either, as the sloppiness appears to be a result of the cables and the internal design of the transmission more than the shift linkage itself. When we later, installed a RAZO shift knob that was a few inches taller, the shift effort improved dramatically. Since the knob effectively brought the top half of the shift linkage back to its original length, the lever ratio was somewhere between its original value and the ratio provided with the stock, knob. Another improvement to shift effort came when we installed our Exedy clutch. The three-puck clutch disc has less rotational inertia than a fully faced clutch disc. and since the syncros have to accelerate or decelerate the clutch disc whenever you shift, less inertia makes the syncros work faster.

We also changed to Motul synthetic transmission fluid at the same time, which also helped speed shifting (since we did the clutch and fluid at the same time, it is impossible to tell which made the bigger difference). Shift effort while driving is nearly the same as stock now, but first and reverse are still much more difficult.

[RRE Note: We were not happy with the performance of either the Pace Setter Short Shifter or the Exedy Clutch, we do not recommend either one.]

Next the trim panel over the ventilation controls must be popped off, Just get your fingers behind it and pull.

The RAZO shifter was originally installed for a show, as were a set of RAZO pedal pads. We were initially planning on removing them after the show, but when we discovered the improvement the shift knob made, we decided to leave it in place. Something similar happened with the pedal pads. Installing the pads not only makes the pedal surface larger and grippier, it also makes it closer to the driver, since the pads themselves are at least a quarter inch thick. Since most of the staffers driving the Eclipse on a regular basis are over six feet tall, nobody wanted the pedals any closer to them. The brake and clutch pedal pads came off almost immediately. The gas pedal pad, on the other hand, turned out to be very functional. The stock pedal is too small, too low, and too far from the brake pedal to be able to heel toe downshift. The pad moved the pedal just far enough to make the car much easier to drive. It my look a little funny, but having only the gas pedal pad in place worked perfect for our picky drivers

It may look a little funny, but having only the gas pedal pad in place worked perfect for our picky drivers

Once it is revealed, the shifter is fairly easy to replace

SCC Magazine – Project Eclipse – Part Five

by Dave Coleman

PHOTOGRAPHY: LES BIDRAWN, KEITH BUGLEWICZ, DAVE COLEMAN

A 28-Horsepower clutch? well sort of ….

Project Eclipse has been the recipient of a very successful series of modifications. From the beginning, nearly everything we did to the car yielded very positive results. That all stopped with out last installment (September, 1998).

As you may recall, our last series of modifications began with a Hahn Racecraft (HRC 3-inch downpipe and high flow catalytic converter. That piece increased airflow so much that the fuel system maxed out the stock injectors just trying to keep up. This lead us to install larger, 550-cc/min injectors from RC Engineering and a larger fuel pump from Road/Race Engineering. The larger injectors required that we adjust the Apex Super AFC (the AFC adjusts the stock air mass sensor’s output so the computer can be fooled into delivering the shorter injector pulses needed for the larger injectors), Being short on time, we made our adjustments quickly and largely by the seat of our pants (and with the help of an Apex exhaust temperature gauge). The result was a car that sounded cool, sucked down a lot more gas, and made exactly the same power as it had before this series of changes. We were confident,, however, that the only reason the changes had not made power was the sloppiness of our tuning.

Shortly after we discovered the lack of improvement, we took the car back to Mike Welch at Road/Race for a more careful tuning session. Welch has tuned numerous Eclipses with the Super AFC and has the procedure pretty well nailed down. First, he plugs a laptop computer equipped with OBD Tool software into the diagnostic plug under the dash The OBD Tool software not only allows you to read the fault codes from the OBDII system, and to reset those fault codes (thereby turning off that annoying “check engine” light), but it also allows you to monitor and data log many of the stock ECU inputs or outputs.

There are five knobs on the Super AFC, each offsetting the air mass sensor’s output at a particular engine speed (the AFC creates a smooth line between these points to establish an overall offset curve). The first knob, which sets the 800-rpm point, is adjusted by simply letting the car idle while monitoring the 02 sensor voltage with the OBD Tool software. With the knob adjusted properly, the 02 sensor’s reading should constantly cycle up and down as the computer operates in its self adjusting closed loop mode. Given the fact that the RC Engineering injectors are 23 percent bigger than the stock injectors it is surprising that the first knob is turned down only a few percent to idle properly

For the next two knobs, covering the 2400 and 4000-rpm points, Welch adjusts them by logging 02 sensor voltage at full throttle in fourth gear. Using a lower gear would not load the engine enough, nor would it allow the engine to be in that rpm range long enough to easily see what is going on. Ideally, 02 sensor voltage should be about 0.94 volts as seen on the OBD II Tool. Under these conditions; ours was 0.98 volts when we brought it in-way too rich, according to Welch.

Finally, the last two knobs (5600 rpm and 7200 rpm) are adjusted by watching exhaust temperature at full throttle in fourth gear. It doesn’t take a rocket scientist to realize that watching the exhaust temperature gauge at the top of fourth gear requires either a closed race track or a trip to Montana with a notebook full of explanations for why 130 mph is reasonable and prudent. According to Welch, the exhaust temperature should be about 600 degrees C (about 1650 degrees F) at high rpm under maximum load. Before Welch made the adjustments, exhaust temperature never went over 800 degrees C, another sign that the engine was running too rich.

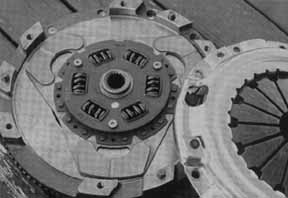

Our new Exedy clutch combines a three-puck cerametallic friction surface with a sprung clutch disc to provide incredible gripping power and heat resistance with reasonable driveability.

[RRE Note: we were not happy with the performance of the Exedy clutch and do not recommend it]

Even after tuning the AFC, Welch felt the car still wasn’t running right. No matter how he set the boost controller, boost pressure would always drop to about 15 psi by redline. With a stock turbo, this is to be expected, as it can not move enough air to make more boost at high-rpm. Welch’s experience with the Turbonetics-upgraded T28 turbo we were using, on the other hand, told him there should be more boost available. After investigating a few dead ends, the OBD Tool again offered the answer. By data logging speed and rpm during a hard fourth-gear pull, Welch noticed that instead of speed and rpm increasing in lock step as they should, the rpm line would start climbing away from the speed line. The only explanation was a slipping clutch.

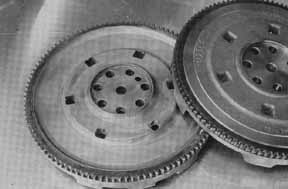

The Road/Race flywheel has four pounds of iron machined away, The majority of that weight was removed from the outer portion of the flywheel where the change can make the most difference. The stock flywheel on the right shows how much metal was removed.

A slipping clutch explains a lot about our experiences with the Eclipse. First, the loss of boost came from the loss of load. Spinning the clutch is easier than accelerating the car, and the lighter loading on the engine reduces the amount of boost it builds. A slipping clutch could also explain some of our inconsistent power measurements. From one installment to the next we have noticed some strange variations; in the power output of our all-wheel drive Eclipse as measured by our Vericom. Some of the variation could have been caused by differences in temperature affecting intercooler performance, or by the ECU switching to extra-conservative fuel and timing maps as weather conditions changed. Now we can add a slipping clutch to the list of things that could be changing power output at the wheels from run to run.

Given our Eclipse’s tremendous power, immense weight (over 3500 pounds with a driver) and all-wheel drive grip, a slipping clutch is no surprise. In fact, you might call it a design feature. In most cars, the clutch is designed to slip before driveline parts start to break- This is especially true of all-wheel drive Eclipses. With 210 horsepower and all wheel drive, there is a natural tendency for every common-sense-challenged yahoo who gets behind the wheel to try and spin all four tires. To save countless thousands of dollars in warrantee claims resulting when these same yahoos find out the transmission isn’t up to the task, the clutch in the GSX was designed with two safety features: An overall capacity a little on the low side, and a damper in the clutch’s hydraulic system that slows the clutch’s engagement when that yahoo makes his or her attempt. While the damper was not getting in our way (the clutch slipping problem only occurred at high boost, well after the clutch was fully engaged) the low capacity of the stock clutch was a problem.

With 210 horsepower and all wheel drive there is a natural tendency for every Common sense challenged Yahoo who gets behind the wheel to Try and spin all four tires

Now that we have learned that our stock clutch has been slipping for an indefinite period of time, we can’t be sure how accurate any of our previous runs were. Power output may have been lowered by the clutch on any of our previous runs. According to the now questionable readings of our Vericom, the new clutch, along with the downpipe and injectors, gave us a huge gain of 28 horsepower. Based on comparisons with rated flywheel horsepower versus Vericom horsepower on our Sentra SE-R (Technobabble, May ’98), we estimate the Eclipse’s flywheel output to be at least 294 horsepower.

Before installing a higher-capacity clutch, we made some 0 to 60 runs to get some objective idea of how much of a difference the new clutch was making. Launching a turbocharged all-wheel drive car is a challenge. While the tremendous grip can give you a serious advantage off the line, getting the car to leap off the line without either bogging before boost is built, or belching the transmission out the bottom of the car is a challenge. The fastest launches came by bringing the engine up to about 3000 rpm, and rapidly feeding out the clutch and feeding in the gas at the same time. Using this technique we were able to pull off one impressive 5.63-second run, followed by the distinctive stench of clutch flambé. The heat generated by that one launch was all the clutch could handle. After that one clutch-smoking run, we were never able to pull off another sub-six second pass.

Our new clutch would have to be significantly stronger, but since the Eclipse is still a street car driven almost every day, we needed it to provide good driveability without excessive pedal effort or chattering during engagement. Our decision to try a three-puck cerametallic

Exedy clutch may seem like a surprising choice oven our requirements. In most cases such a clutch would grab so suddenly and chatter so badly that it would be absolutely undriveable. Street clutches are typically designed with a sprang disc, meaning that the center of the clutch disc-where power is delivered to the transmission-is isolated from the outer edge of the disc-where the disc is clamped by the pressure plate by several springs. These springs smooth the clutch’s engagement. Most cerametallic clutches are designed with a solid disc simply because most sprung discs can’t handle the higher torque load. While it seems like the obvious solution is simply to build a stronger sprung disc, most performance clutch manufacturers make their clutches by modifying stock parts. Building a whole new disc would make the parts prohibitively expensive. Building performance clutches by modifying stock parts certainly works, but it does place some limitations on the design. Exedy, on the other hand, is a OE clutch manufacturer (Exedy actually owns Daiken Clutches), and they therefore have the facilities to be able to engineer and build clutches that most low volume manufacturers would not be able to. Hence their claim that their three-puck cerametallic clutch could be used on a street car.

The OBD Tool software Is used to monitor engine functions as tuning adjustments are made. The jagged line here is O2 sensor voltage cycling up and down as the computer self-adjusts fuel mixture at idle. The 800-rpm knob on the AFC must be set within the proper range to allow the computer to do this.

Here the OBD Tool is showing the data logged run that first revealed slipping clutch. The line on top is RPM, while the line on the bottom is speed. Both should increase together, but because of our slipping clutch, the rpm increased more than the speed.

That sounded like the perfect solution, so we decided to put their claim to the test. The Exedy clutch has a clamping force of 880 pounds compared to the stock clutch’s 700 pounds, but because the three-puck design concentrates that force into much smaller area (only three pucks instead of a full disc) the pressure on the friction surface is event higher. The result is an overall torque capacity 63 percent higher than the stock clutch.

When Road/Race installed the clutch, they suggested installing a lightened flywheel as well. While the Road/Race flywheel is only 4 lbs lighter than the stock one (14 lbs vs. 18 lbs), most of that weight has been removed from the outer edge of the flywheel where it can make the most difference. Since rotational inertia goes up with the square of the distance (in other words, removing weight from the outer edge will make four times as much good as removing it from halfway out from the center) where you remove weight makes much more difference than how much you remove.

After installing the clutch and flywheel, Welch drove the car for a day to help us break it in. Initially, he reported, the clutch did chatter and grab rather severely, but as the clutch broke in, engagement smoothed considerably Only a few days of normal driving were required before the clutch began to behave in a civilized manner Pedal effort is quite high, even though spring force is only 25 percent higher than stock. The fact that the stock clutch’s effort is already quite high makes 25 percent a significant difference. The clutch is also slightly grabby as any clutch this strong has to be, but overall, if you can cope with the clutch on an early ’80s Porsche 911, you cope with this one.

Next came the tests. With the clutch broken in, we returned to our 0-to-60 mph test. Launching the car is not really any easier with the stronger clutch-engage it too suddenly and you can still bog it quite easily, but now excessive slippage will not overheat the friction material. Much like brake pads, an organic clutch facing material will tend to “float” when overheating causes resins in the facing to bum off. The cerametallic facing has no such problem-heat has very, little effect on our new clutch’s performance. Excessive slippage is still a bad idea, though, as the clutch will tend to grab and chatter if you launch at too high an rpm. Once we found the sweet spot, though, the all-wheel-drive Eclipse launched with such ferocity that it could actually chirp the front fires.

From the first 0 to 60 run it was clear that the new clutch was not slipping at all. Previous runs required either you either to shift to third gear or push the engine a few hundred rpm past the redline before reaching 60 mph. With the new clutch, redline took the car all the way to 68 mph-proof that the stock clutch was slipping at several hundred rpm even in second gear!

Our best 0 to 60 run was an impressive 5.54 seconds, an improvement of almost a tenth of a second. Even more significant was the fact that while the stock clutch could only handle one good run before overheating, the Exedy clutch withstood run after run, back to back, with out ever running longer than 6 seconds. in fact, our best run was on the third attempt.

Once we found the sweet spot, though, the all-wheel drive Eclipse launched with such ferocity that it could actually Chirp the front tires.

The final test was to do some second gear pulls with the Vericom to determine our power output. This would be our first chance to finally evaluate the performance of the HRC downpipe and catalytic converter and the 550cc/min RC Engineering injectors, as well as the Exedy clutch and Road/Race flywheel, and the fine tuning work performed by Road/Race. To our great relief, peak output was up 28 horsepower. This is especially impressive when you remember that we are still using the tiny stock intercooler. The peak power reading given by our Vericorn is 210 hp, but as we discovered in our dyno comparison test several months ago (Technobabble May, 1998), the Vericom’s readings are consistent and precise, but quite a bit lower than a Dynojet. Our test of a 140-hp Sentra SE-R registered only 100 hp on the Vericom (and 117 hp on several Dynojets). Since our Eclipse’s output is 2.1 times that high, we can confidently estimate flywheel output at a bare minimum of 294 hp.

In reality, the GSX’s all-wheel drive system has to have higher driveline drag than a front wheel drive SE-R, so real flywheel output must be well over 300 hp.

We have seen this phenomenon before, but it is always interesting to see it happen. The HRC downpipe and cat, and the RC Engineering injectors obviously did their job and did it well, but simply slapping them in place and hoping for them to work won’t cut it. An engine is an amazingly complicated system and whenever you mess with one variable, you invariably will affect another one. in our case the increased air and fuel flow had to be properly adjusted to create power, and then the clutch had to be strengthened to actually harness that power. People are constantly asking us how some combination of parts will work on their car. Results like this are the reason why our answer is almost always “it depends”.

Marc S – Carlsbad in July – 12.14, clutch-limited..

I’m exhausted as hell so this will be shorter than my usual novels (but

still long) :)

– Billy ran an 11.97 I believe. YES! Finally an 11, now him & I can go

home & rest for the next few weeks, we are sick of going to the track

trying to get that 11 we both knew we could run :). Major congrats!

– I got a personal best of 12.14 @ 113mph. I continued to have major

problems launching… 60-foot times were mostly 1.8’s and 1.9’s. Highest

MPH for me was 113.6 mph. Other runs included: 12.15 @113.4, 12.18 @113,

12.18 @113 (another), 12.18 @112, 12.24 @113.2. I’m confident the car

could run 11’s… All it needs is a good launch… And/or remove the

headlight… And/or take off some weight like Billy :) hehe… Or add the

ITC… Or… :) But the bottom line is now that 11’s have been done I’m

taking a rest from racing for a month or longer & when I come back likely

it’ll be with additional stuff so I don’t have to just “squeak” an 11… And

I’ve got to figure something out about this whole clutch/launching

situation… Maybe re-treads for traction… Who knows. 4 puck clutches just

don’t seem to be the way to go for launching…

– Carlsbad… Anyone who went to Pomona missed out. Anyone who did not go

racing PERIOD missed out. There were 40 cars total at Carlsbad. I got

*16* runs in when I finally “had my fill”… Coulda kept going and probably

had 20+ runs! That’s 16 runs in about 2.5 hours time (2pm to 4:30pm).

Pretty insane! There were never more than 4-8 cars in front of you in

line! Weather was warm but the air wasn’t too hot unlike Pomona last week.

– DSM’s @ Carlsbad… Well, we just had our “West Coast Shootout” :).

Nearly 1 out of every 4 cars there was a DSM! We had about 9 cars (one

DSM wasn’t a Club DSM’er). With 4 of us running 12’s and 3 of us running

really low 12’s (and an 11!) we dominated and kicked muscle-car a$$. The

good ol’ boys were commenting how we were mopping up. I really enjoyed

killing some of the big loud big block slick wearing and super-charger

breathin’ brutes :)… We popped a lot of ego’s today :)

– We had an awesome drive after leaving the track with 7 DSM’s… The road

was 3 lanes wide, so we had 2 rows of 3 DSM’s (With Steve H. in the rear

trying to snap a picture)… Felt like I was in a fighter plane formation :)

– Personal thanks go out to Scot Gray & Henry S. Scot let me borrow his

BFG TA R1’s to try to get more traction (couldn’t get them heated up enough

w/ drag racing so they weren’t as grippy as we were hoping) and Scot and

Henry were both a killer pit crew changing the tires back & forth :).

– On a final note… Damn DSM’s are built tough :)… In the past week I

have put *27* 12 second passes on this car, mostly low 12’s, without a

glitch (knock on wood). Mike Ferrara wouldn’t like it! :)

Hope you all had a good 4th.

-Marc

Marc S – Pomona in June – Awful new clutch, but 12.16 / 114mph

The good:

– The Pomona guys said it was the smallest turnout all year. We averaged

a run per hour for the first few hours, and then around 2:40pm it started

to become “run as often as you want”… You just ran & got back in line

again (with between 16 – 40 other cars!) So we ended up paying under a

dollar per run if ya don’t count the race gas :)

– Scott Terrace ran some awesome times, especially with his very short

list of mods… 13.3’s! This is right up there with those ol’ East Coast

stories of putting under $1000 into a DSM & being at low 13’s… Scott is

going for 12’s soon on the ultimate budget car!

– Bryan actually showed this time (hehe) and broke 13’s on his 14B car!

Yeeha!

– Had a first-timer come (I just know I’m gonna spell this wrong…

“Shino?”) and do awesome! Shino has a 2G FWD with limited mods and by his

3rd launch he had pulled a 2.3 60-foot time! He later pulled at least 2

2.2 60-foot times! (1/4 mi time was 14.6 I believe). Fantastic times for

a FWD & a first time at the track. Congrats!

– I had a new personal best & my MPH increased substantially.

The bad:

– Most of my times! Yeah, I know these times are faster than most, but

honestly the car has more in it so considering I started the day at a 12.19

@ 114.3 w/ a 1.857 60 foot time, the day was very disappointing for me.

The ugly:

– My 60-foot times were horrid. I could not launch the car worth a damn

with the new clutch. I wanted to rip that thing out and torch it. Even

with *11* runs (towards the end I was trying ANYTHING to see if I could

figure out a method to launch) I couldn’t do jack on my launches… Here are

some of the timeslips, then I’ll mention the “why”…

12.16 @ 114.5, 1.807 60-foot time

12.19 @ 114.3, 1.857 60-foot time

12.19 @ 114, 1.763 60-foot time (hit rev limiter bad on 1-2 shift)

12.32 @ 113.5, 1.897 60-foot time

12.32 @ 113.2, 1.922 60-foot time

12.34 @ 114, 1.895 60-foot time

12.40 @ 114.4, 1.972 60-foot time

Other 60 foot times included: 2.071, 1.971, 2.036, 2.254.

The day started off exciting… We knew on the first run that the engine was

11-second capable. Had the MPH, just needed a good launch… If I coulda

had a 1.71 60 foot time on that 12.19/1.857 run, the 12.32/1.922 run,

etc… Coulda grabbed an 11.9x. We all knew it and as the day went on I

was really really frustrated at not being able to improve the launch.

Here’s what was happening in-car:

I’d take the engine to various rpm, usually no less than 4500, and then

when it was time to launch I’d start stepping on the gas and then start

releasing the clutch. No matter how fast or slow I seemed to release the

clutch pedal, within the first few feet of launching, suddenly I’d hear

loud bangin’ noises coming from all 4 tires. The car ran *perfectly*

straight off the line and down the track, was not squirmy in any way. So

what did I figure? I thought I had wheel hop… That the tires were right

on the border of hooking up/not hooking up and were going back and forth

between the two, hence the physical banging I was feeling/hearing. (Every

launch now activated my windshield washers, too, so it seemed like I was

getting decent traction).

So stupid me, I spent almost all my runs trying to get the wheels spinning

a little more… I raised the RPM level of my launches, tried slipping the

clutch even more (it doesn’t like to slip at all), etc. I didn’t want to

be on the edge of traction… I wanted to have my wheels spinning more

cleanly for a little off the line, and then have them hook up solid… This

is how I got my low 1.7’s before, because the car still accelerates strong

with the spinning, and you don’t bog your engine. Most of the runs

Saturday I’d hit the rev limiter on the 1-2 shift too… Suddenly it would

jump to 7200 on my tach (my tach reads 300 rpm low) and there would be no

time to shift to 2nd before the limiter hit…

Realization of what was happening didn’t come until the 9th friggin run…

(I was kinda out of it the whole day from getting 3 hours max of sleep). I

can’t remember exactly how it happened but I mentioned to someone how I hit

my rev limiter at the 1-2 shift at my last run, and they responded “yeah,

you were in that rev limiter for a while”… (And I was thinking “that’s

odd, when rev limiter hits before I can shift, it’s usually pretty quick).

The spectator describes how my engine sounds *off the line* before I even

got to shift… Brah-brah-brah-brah (stutter stutter stutter). Ronnie comes

by & he confirms the prob… I was riding the rev-limiter throughout the

launch! It was impossible to hear the rev-limiter with helmet on, windows

closed, and big loud sounds coming from all 4 tires… Yeah, you could call

it wheel hop, but not because I was on the verge of traction… It was

because the engine was making so much power it was just annihilating all 4

tires and instantly going to rev limiter the whole way through 1st… As the

rev limiter hit, the wheels would go back & forth between gaining a touch

of traction & losing it again. The wheels were all spinning so evenly that

the car never felt squirmy in any way and simply stayed straight…

So yeah, I was running low 12’s with riding the rev limiter throughout

first gear. Engine made lots of power, clutch grabbed hard, tires couldn’t

hack it in any way. Plain & simple. Nice to know the why, but there

wasn’t anything I could do to go faster… Just couldn’t get any traction

with such a harsh clutch. The clutch did its job of holding the power. It

just did it too well! End of story.

I am gonna see about getting my rev limiter raised to 8000, perhaps that

will help a little… Now I know how a FWD’er with a built engine and no

slicks feels. I honestly think though that if I had my “old” clutch in the

car (before it blew a spring), 11’s coulda been mine :). Time to invest in

some tires.

Which leads us to today (Sunday)-

Billy- Kick some butt and bring us that 11-sec time slip we’ve been waiting

for… Our cars are definitely good for it. As long as you didn’t get my

type of clutch installed last night you will do just fine :)-. Good luck

to Josh too!

Marc S – Carlsbad in June – 12.20, but bye-bye clutch

Lots of mixed Carlsbad news… This will be lengthy.

Twas a very hot day which sucked for getting good times… On the positive

side it wasn’t too crowded, I got 5 runs in between 2pm and 4:15pm before

my car called it quits :(.

Run 1. First run had me really, really worried. 12.75 @ 105, w/ a 1.77 60

foot time. The car was hot & one or two of my shifts wasn’t quite as fast

as usual but that time was really off!… Checked peak EGT… 810 degrees…

Ok, running too rich. Leaned things out a couple notches.

Run 2. 12.34 @ 110. Phew, getting better, new personal best. 1.71 60

foot time. MPH still has me worried though. Was already getting 110 at

Pomona, before the cams, and the cams definitely have the car pulling

harder. Checked EGT’s… Still low. Leaned things out a touch more.

Run 3. Off to a decent start. 1.75 60 foot time, 7.89 ET in the 1.8th,

and 1/8 mph is almost 1 MPH higher than Run 2… Go to shift from 3rd to

4th… I don’t think I had my clutch pedal in all the way in time as I jam

it to 4th… But the *shifter* goes into 4th anyways but feels like it has

no weight when it gets there. Step on the gas but I’m not in gear, the

engine just revs. No 4th gear. For that matter, no any gear, the shifter

moves into all the gears with almost no resistance & I’m “in neutral”.

$h!t. Now I’ve done it! I coast through the 1/4mi – 12.98 @ 85mph!

What a run that woulda been if I had 4th gear :) My MPH in the 1/4 was

less than my MPH in the 1/8 and it was still a 12 :). I come to a stop at

the entrance to the return road (end of the strip), put on the hazards, but

the lazy Carlsbad officials just stare at me… So I think about it as I

move the shifter around… Ok, no resistance at all, & always in neutral…

Almost as if… The shifter ain’t attached to the cable no more! I yank

the plastic panel off under the shifter & look down there… Yep! The

cable came off. (It lost the cotter pin). I put it back on, get it in

gear & am on my way. Later I rigged a new pin by bending a key ring…

Problem solved.

Run 3 gives me time to think… Why are my EGT’s still so low, and what’s up

with the MPH (1/4 MPH for Run 3 was unusable but 1/8mph showed very minor

gains)… Then it dawns on me… My boost is low. Never raised it on the

way to Carlsbad. I had set it late the night before when the air was very

cold. I was probably running 18-19psi in the heat!… Up the boost a

touch… Time for run 4…

Run 4. Got a decent launch, but had a bog problem which to be honest

plagued me on all the runs… I’d get off the line quick w/ spinning tires

but would then hook up early, have a quick bog, and then take off. This

likely affected all my times that day. Gotta do some tuning, the cams

changed a lot of things. 1.73 60 foot time. 1/8th: 7.78 @ 88.35. 1/4

mi: *12.20* @ 109! I’m excited about the ET but still puzzled about the

MPH. For comparison, I ran 86-88mph in the 1/8th at Pomona in my 12.4 –

12.5 runs & always 110mph in the 1/4. I up the boost a little more (it was

probably still a little low, 19-20) & lean things out a little more in

preparation for Run 5. Looks like I will get several more runs in so I

have time to tune in small increments.

Run 5… Disaster strikes. The run was bad from the very start. For the

first time, my less-than-happy-to-disengage-when-hot clutch has a very

noticeable impact at the track. I try to shift to 2nd & it doesn’t wanna

go in. Wait for it to drop in (the run is totally blown now) and I

continue on… The rest of the shifts ain’t feeling too good. Cross the 1/4

at 13.3/107.5 & the shifter doesn’t wanna come out of gear. I manage to

get it out & am barely able to force it into a lower gear to get back to

the pits. Park the car, figure I’ll let it cool down while I grab lunch &

hope it’ll get back to normal like it usually does once it cools.

No dice this time. I go start up the car. With the clutch pedal pressed